Headstamp Gude - Letters - B

B

A Brief History

Federal State Unitary Enterprise Production Association "Vympel"

Shosse Mashinostroiteley 12, Amursk, Khabarovsk region, Russia 682640

Telephone: +7 (42142) 2-57-25

Fax: +7 (42142) 2-77-23

Vympel Website

A Brief History

OJSC “The Tula Cartridge Works”

47-b, Marata Str.

Tula, Russia

fax: +7-(4872)-41-11-74

е-mail: info@wolfammo.ru

From Website:

The history of the Tula Cartridge Works dates back to the year of 1880, when on the 17th of May the emperor Alexander II approved the regulations of Military Council on establishment of the ammunition plant with attraction of private сapital. The right to establish the plant was granted to the collegiate assessor Theodor George von Gyllenschmidt (1828 - 1903).

The Gyllenschmidt's plant was designed to produce small-caliber 4,2 - line (10,67 mm) cartridges for Berdan N2 infantry rifle. Later on the plant also produced cartridges for 1891-year model 3-line rifle, revolvers and shotguns.

In 1880 the construction of the plant was over and a contract was concluded with the State Ordnance Bureau (GAU) for the delivery of 210 million rounds during 7 years.

In 1882 the plant began to operate at full power - 30 million rounds a year.

In 1886 the brass-rolling mill and the copper foundry were built which fully supplied the production of ammunition.

During the years of World War I the Tula Cartridge Works supplied the Russian Army with approximately 25% of all ammunition manufactured by domestic plants.

In 1918 the ammunition plant in Tula was nationalized.

The first five-year plan provided for fundamental reconstruction of ammunition production with a view to develop productive capacity on the basis of raising the technical level and providing the increase in labour productivity.

Owing to unfitness of the old factory buildings for reconstruction, provision was made for construction of new buildings where the base of ammunition production was transferred upon realization of the project in 1929-1931.

Used for manufacture of cartridge cases up to the late 1930s was brass, for manufacture of bullet jackets - German silver. Brass and German silver were scarce raw materials.

In 1928 for the purpose of saving strategic non-ferrous metals the government set a task to organize and master the production of bimetal on the base of ammunition plant.

The construction of the shop for production of bimetal in Tula began in 1929.

In 1930 the equipment began to arrive at the plant from Germany.

In 1932 the rolling-mill shop began to produce bimetal for the first time in Russia.

In 1933 mastered for the first time in ammunition production was the manufаcture of cemented-carbide tools.

Thus, in Tula during the first five-year periods put into operation was practically the new ammunition plant to provide the growth of ammunition output at a considerably higher technical and organizational level.

On the 14th of September by decision of the government the ammunition production was granted the status of economically independent enterprise. And in 1941 it was named after S.M.Kirov.

In the pre-war period the Kirov Works produced 7,62 mm cartridges for machine-gun "SHKAS", 7,62 mm rifle cartridges, 7,62 mm pistol cartridges "TT" and cartridges for revolver "Nagant".

The increase in output was provided by the advancement of the technology of ammunition and tool-making production , renewal of equipment and, mainly, by automation and mechanization of production processes.

From the beginning of the Great Patriotic War to October, 1941 the plant provided uninterrupted supply of the front with ball cartridges. In October, 1941 the plant was evacuated to the town of Yuryuzan, the Cheliabinsk region, the rolling-mill base was transferred to the town of Nytva, the Perm region.

In connection with the successful offensive taken by the Read Army in the environs of Moscow and Tula in November - December, 1941 the plant was set а task of restoring the production of ammunition for our army.

With a view to restore the ammunition production, dismantled at the enterprises of of local industry and delivered to the plant were about 100 units of metal-cutting and pressing equipment.

Shipped from related enterprises was the minimum quantity of equipment for production of 7,62 mm cartridges, tools, materials, and in April, 1942 the plant was again officially registrated as individual enterprise. In 1942 produced by the plant were over 100 000 rounds, by the end of 1943 - over 388 million rounds.

In 1949 our plant was one of the first in industry to get down to work on development of processes for production of ammunition on automatic rotor lines (ARL).

In 1959-1965 created was an integrated and automated production of steel cartridge-cases.

In 1966-1970 the work was continued on further introduction of rotor lines into ammunition production, development of the plant's own ARL designs and introduction of rotor lines into other kinds of production. Much attention was also given to creation of integrated, highly mechanized and automated shops and bays on the base of ARL.

In 1971 for introduction of new techniques the plant was decorated with the Order of the Red Banner of Labour.

In 1973 the plant was the first in industry to master the production of 5,54 mm cart-ridges for AK-74 submachine gun and became the base one in the industry on development of production processes for this ammunition.

In 1974 the reconstruction of the rolling-mill production was over and the first lot of bimetal was produced by method of cold cladding.

The work on theoretical substantiation, development and introduction of the original highly efficient process of production of bimetal by method of cold cladding was awarded the USSR State Prize.

The Tula Cartridge Works exerted a considerable influence upon the development of the ammunition industry of Russia - automation and mechanization of production processes, mastering mass production of precision instruments and measuring tools, mastering methods for manufacture of tools from hard alloys, mastering production of bimetal N1, N3, mastering the process of production of bimetal by method of cold cladding, mastering the production of 5,45 mm cartridge for AK-74 submachine gun.

In 1991-1997 the J-SC "TCW" mastered the new line - production of ammunition for sporting and hunting arms (PSO). At present the ammunition production turns out sporting and hunting ammunition in calibers 5,45 x 18; 5,45x39; 7,62x39; 5,56x45 "Remington"; 5.56x39 "Bars"; 9x17 "Kurz"; 9x18 "Makarov"; 9x19 "Luger"; . 45 AUTO etc.

Mastered has been the production of ammunition for service firearms: 12,3x22; 12,5x35.

WOLF-under this trademark the Tula-made sporting and hunting ammunition is known and sold abroad.

A Brief History

Barnes is a producer of various types of bullets, including all-copper bullets.

A Brief History

Barrett Firearms Manufacturing, Inc.

P.O. Box 1077

Murfreesboro, TN USA 37133

Phone: (615) 896-2938

FAX: (615) 896-7313

Email: mail@barrettrifles.com

Barrett Firearms Manufacturing, Inc. of Murfreesboro, TN, circa 2007. Proprietary cartridge .416 Barrett, 10.5x83mm, .416/.50, for the commercial US market. The .50 BMG case necked down and cut back for a .416 caliber projectile. Bullet is a brass, monolithic solid match design. Brass case, brass percussion, non-corrosive, boxer primer, no primer sealant or primer crimp, headstamp "Barrett .416" From black, 10-round, cardboard boxes, with white printing & Barrett logo. Lot # 022707.

A Brief History

Barrett Firearms Manufacturing, Inc.

P.O. Box 1077

Murfreesboro, TN USA 37133

Phone: (615) 896-2938

FAX: (615) 896-7313

Email: mail@barrettrifles.com

Barrett Firearms Manufacturing, Inc. of Murfreesboro, TN, circa 2007, on .50 BMG caliber M33 Ball ammunition manufactured for them by CBC (Brazil), for the commercial US market. 661 gr FMJBT, copper-jacketed, mild-steel (not AP) core projectile, with knurled crimping cannelure. Brass case, brass percussion, non-corrosive, boxer primer, purple primer sealant, 3-stab crimp. From black, 10-round, cardboard boxes, with white printing & Barrett logo. Lot # BI0830 L-143.

A Brief History

Produced by Belom ammunition factory, which operates under the Serbian state-owned weapons manufacturer, Yugoimport SDPR and was founded by BORBENI SLOŽENI SISTEMI in 2015. Current products include 9mm Luger, 7.62x39, and 12.7x108mm calibers.

Contact information:

31210 Pozega, Serbia

A Brief History

Info listed from box:

Dynamic Research Technologies, LLC

5925 300th Street

Albany, MO 64402

Phone: 660-564-2331

FAX: 660-564-2103

Email: info@drtammo.com

www.drtammo.com

DRT produces frangible ammunition.

BGA - Black Gun Ammo, a product of BlackGun Industries.

http://www.blackgunindustries.com/pages/about-us

A Brief History

Black Hills Ammunition

PO Box 3090

Rapid City, SD 57709

Phone: (605) 348-5150

Fax: (605) 348-9827

A Brief History

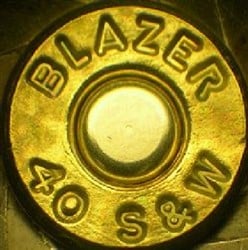

CCI/Speer

2299 Snake River Avenue

Lewiston, ID 83501

Phone: (866) 286-7436

Email: blazerammoexperts@atk.com

Blazer Website

A Brief History

Black Hills Ammunition manufactures various handgun and rifle caliber ammunition. According to their website, their ammunition is used for testing and development at a number of firearm manufacturers across the country. The products the sell also feature headstamps of BHA, Hornady, and Starline.

Contact information:

Black Hills Ammunition

PO Box 3090

Rapid City, SD 57709

Phone: (605) 348-5150

Fax: (605) 348-9827

A Brief History

Italian maker of shotshells for a variety of purposes, including hunting, sporting, and law enforcment.

A Brief History

Sellier & Bellot JSC

Address: Lidická 667, 258 13 Vlašim, Czech Republic

Phone: + 420 317 891 111

Fax: + 420 317 892 489

E-mail: info@sellier-bellot.cz

Sellier & Bellot Website

Sellier & Bellot, U.S.A.

P.O. Box 7307

Shawnee Mission, KS 66207

Phone: (800) 960-2422

Fax: (229) 723-8748

Sellier & Bellot USA Website

From Website:

Dates of Significant Events

5th August 1825

Louis Sellier, a French merchant, received the privilege to manufacture percussion caps for infantry firearms in its newly founded factory in Prague from Franz I., the Emperor of Austria. Shortly afterwards he invited his countryman, Jean Maria Nicolaus Bellot, to join the company. Under his leadership the manufacture quickly gained momentum and Sellier & Bellot products soon established themselves on both European and overseas markets. As early as 1830 the manufacture of percussion caps was in excess of 60 million and peaked later in 1837 by enormous quantity 156 millions caps.

1829

A subsidiary plant in Prussian Schőnebeck was founded.

1835

Sellier & Bellot was appointed the Emperor‘s official supplier.

1870

Cartridge production started. Together with Flobert‘s rimfire and Lefaucheux‘s pin-primer cartridges, first centrefire cartridges appeared in the production program. During few years, the annual output grew up to 10 millions cartridges.

1884

Another subsidiary plant was established in Riga (Latvia) and this soon covered demands for percussion caps in the whole Russia and Scandinavian countries.

1893

The first trade mark Sellier & Bellot has been listed in Prague.

1895

Hunting cartridge cases, quickly followed by hunting cartridges, were brought into the production program. This program was also extended by copper primers for blasting works and ammunition manufacture in Skoda Pilsen.

1914 - 1918

During the years of World War I the production of commercial ammunition was curbed and total capacity used to manufacture rifle and handgun cartridges for the Army. The Steyr 9 mm cartridge was developed and introduced to serial production during this period. After the independent state of Czechoslovakia was founded in October 1918, the Company became the dominant supplier of handgun ammunition for the Czechoslovak army and police. The production of commercial ammunition for competition shooting and hunting purposes was further extended. The Company expanded into the Asian and South American markets where Sellier & Bellot‘s infantry cartridges met with a great success.

Based on the invention of its managing director Mr. Blechta, the Company became the only manufacturer of silver azide in the world. Owing to this, the production of industrial detonators increased significantly.

1936

The Company´s transfer from Prague to Vlašim led to further growth.

1945

Nationalization of the Company and the decision of the Czechoslovak Government to introduce state monopoly for the manufacture of both military and commercial ammunition supplied a key incentive for further development of Sellier & Bellot. The range of commercial ammunition was extended to forty rifle calibre types, ten pistol and twenty revolver types. Shot shells manufacture ranged from 12 to 410 calibre types and total output was soon increased five times. Approximately 70 % of the output was exported. Original 7.62×45, 7.62×39 and 7.62×54R cartridges were successfully introduced into production to cover the demands of the Czechoslovak Army.

1964

Company started to produce antifriction bearings.

1965

Production of packaging machines, now concentrated in the subsidiary company Sellier & Bellot, stroje Ltd. began.

1972

Manufacture of cartridges according to valid C.I.P. regulations was begun.

1992

Transformation of the state-owned company to a joint-stock company - Sellier & Bellot JSC. The company‘s shareholders are Czech natural and legal persons; a part of the equity is hold by Company´s employees.

Almost 70% of production volume is exported through the daughter company - Sellier & Bellot Trade JSC. The company´s products are exported to more than seventy countries in the world.

1998

Sellier & Bellot JSC was granted ISO 9001 Certificate.

1999

Sellier & Bellot has got the bronze medal in Deutsches Waffen Journal readers´ vote for year 1999 in the category of Ammunition.

2005

Sellier & Bellot JSC celebrating its 180th anniversary this year is not only the oldest engineering company in the Czech Republic but also one among the oldest companies in the world. It has been manufacturing products bearing its trade mark uninterruptedly since 1825.

A Brief History

Sellier & Bellot JSC

Address: Lidická 667, 258 13 Vlašim, Czech Republic

Phone: + 420 317 891 111

Fax: + 420 317 892 489

E-mail: info@sellier-bellot.cz

Sellier & Bellot Website

Sellier & Bellot, U.S.A.

P.O. Box 7307

Shawnee Mission, KS 66207

Phone: (800) 960-2422

Fax: (229) 723-8748

S&B USA website

A Brief History

MAC, LLC of Bay St. Louis, Mississippi, primarily known for producing polymer-cased .50 caliber ammunition.

MAC, LLC became part of the Norwegian defence company Nammo, known for their development of ammunition. MAC had previously focused on “development and commercialization of lightweight, polymer-based solutions.” In January 2019, Nammo announced that they had taken majority ownership of MAC.

A Brief History

Barnaul Machine-Tool Plant Website

US Importer

DKG Trading Inc.

8791 Stringtown Rd.

Evansville, IL 62242

Phone Toll-Free: 877-354-2666

Fax: 618-785-2120

Email: sales@dkgtrading.com

Barnaul Ammunition Website

From Website:

JSC "Barnaul Machine Tool Plant" is one of the leading producers of industrial goods and ammunition in Russia. The history of the plant's dates far back in the past to the times of Aleksander I. He was the Emperor who ordered to open one of the first cartridge plants of Russia in St. Petersburg in 1869. Later, during the First World War Russian Army was supplied by it's production. The plant operated in St.Petersburg till the Civil War. When the German Forces were coming to St. Petersburg, the plant was evacuated from the Moscow region to Podolsk city. With the beginning of the Second World War (1941~1945), under the threat of Moscow siege by German Forces, the Podolsk Cartridge Plant was evacuated to Barnaul. It is here where all issues of almost all types of cartridges was started. The first echelon of ammunition for the Soviet Army was sent from Barnaul in about a month. It is well known that almost every second cartridge used by Soviet Forces during the Second World War was produced in Barnaul. The city, where the Barnaul Machine Tool Plant is situated, is in an advantageous geographic position. The presence of all direction railways, one of the main highways of the country and an international airport allows to promote goods successfully. The company has long term and stable contacts with large suppliers of raw materials and also some direct relationships with Russian and foreign firms, whose numbers are increasing. Unique technology and great scientific potential allow us to develop new types of products and to extend their range. The most substantial trend of plant activity is the manufacturing of sporting and hunting cartridges for rifled armor and shotgun cartridges for smooth bore rifles. Ballistic, constructional and exploiting characteristics of sport hunting cartridges do not yield to the best foreign analogues, modern technology of production allows us to keep prices for them stable and competitive. This makes the company one of the largest suppliers of cartridges in Russia and also gives an opportunity to deliver cartridges regularly to the United States of America, Europe and Asia. Such orientation on new development trends in the world ammunition market and ambitions for technology improvement are the central moments in the plant's market policy which provide for the dynamics of it's development.