Headstamp Guide - Letters - O

O

A Brief History

Based out of Opal, Wyoming, their products include handgun and rifle cartridges.

Website:

Contact information:

PO BOX 146,

Opal, WY. 83124

US

info@opalammo.com

A Brief History

From globalsecurity.org:

Ordnance Factories

The Ordnance Factories Organisation is the largest departmentally run production organisation in the country and is engaged primarily in the manufacture of Defence hardware. The organisation functions under the Department of Defence Production and Supplies and is a dedicated facility for manufacture of Arms, Ammunitions and Equipment for Defence Services. There are 39 Ordnance Factories geographically distributed an over the country in 24 different locations. There are 10 factories each in Maharashtra and UP, 6 factories each in Madhya Pradesh and Tamilnadu, 4 factories in West Bengal and one each in Andhra Pradesh, Orissa and Chandigarah.

The history of the Indian Ordnance Factories dates back to March 18, 1802 when its first unit, Gun & Shell Factory, was set up on the banks of the river Hooghly at Cossipore, West Bengal for manufacturing gun carriages. Today, the organisation is a conglomerate of 39 ordnance factories. Its 40th factory is being set up at Nalanda in Bihar for the manufacture of bimodular charge required for the 155 mm artillery gun system. The production value in ordnance has risen from Rs 15 crore in 1947 to more than Rs 6,500 crore by now. The Ordnance Factory Board (OFB), Kolkata, controls and coordinates the activities of the factories. The Director General, Ordnance Factories, acts as Chairman of the Board. The OFB consists of nine members in the rank of Additional Directors General.

The capability of Indian Ordnance Factories was proved once again during Kargil conflict. It emerged as the most reliable source of defence equipment to the Armed Forces. The Ordnance Factories continuously strive for product upgradation.

Out of 39 factories, 16 were set up before Independence. The factories commissioned before Independence had capacities created not only for production of finished stores required by the Armed Forces, but also had backward integrated in-house facilities for supply of basic and intermediate materials for which indigenous civil infrastructure was inadequate. In respect of the factories set up after Independence and with gradual emergence and development of civil industrial infrastructure with public and private sector, the concept of backward integration was progressively given up and the emphasis shifted from production of basic intermediate inputs to production of finished stores by drawing upon supplies from the civil sector for raw materials, components,. semi-finished goods to the extent practicable.

The structure and the management of the organisation had been changed in 1979 for a cohesive, effective and co-ordinated working, based on the recommendations of an expert and high powered committee (Rajadhyaksha Committee). The Ordnance Factory Board was accordingly formed with Director General as Chairman and 9 Members in the rank of Addl. DGOF ; One member is from Finance stream.

At present, Ordnance Factories are divided into 5 operating groups/ Divisions, depending upon the type of the main products/ technologies employed; These are:

Ammunition & Explosives

Weapons, Vehicles and Equipment

Materials and Components

Armoured Vehicles

Ordnance Equipment Group of Factories

Each of the above group of factories is headed by a Member/Addl. DGOF. Armoured Vehicle Division and Ordnance Equipment Division have their headquarters at Avadi (near Chennai) and Kanpur respectively. Three Members in charge of Ammunitions, Weapons and Materials manufacture have their headquarters at Calcutta. The four remaining Members are responsible for staff functions, viz Personnel, Finance, Planning & Material Management, Projects & Engineering and Technical Services and they operate from Calcutta.

Complementing the country’s 4th Arm of Defence, the Ordnance Factories Organisation caters to the requirements of Indian Army, Air Force, Navy, Para-Military and Police Forces of Central and State Governments. There is no proposal for privatisation of Ordnance Factories under consideration by the Government. The Ordnance Factories organization, comprising of 39 factories, are engaged in production of arms, ammunition, equipment, Clothing & General Store items etc. primarily for the Armed Forces of the country.

The countrywide network of the Ordnance Factories has a wide range of technologies and product mix. The factories manufacture a variety of products which can be broadly classified into ammunition and weapon items, armoured vehicles and their variants, military vehicles, clothing and other equipment. Besides, the organisation has production expertise in special-purpose machines, optical and opto-electronic devices and cable and fibre optics. The organisation contributes approximately 44 per cent of the total annual turnover of all the defence production units including eight defence public sector undertakings. It also has 70 per cent share of revenue budget (ordnance) of the Indian Army on an average. since 1999-2000, the Ordnance Factories have started generating surplus.

While design development of any new product is the responsibility of the Defence Research and Development Organisation (DRDO), the Indian Ordnance Factories have their own in-house R&D through which they have been carrying out product and process improvements.

The Ordnance Factories are quite experienced in assimilating transfer of technology from abroad for indigenisation. The Vijayanta and T 72 tanks and related ammunition, infantry combat vehicles along with their arms and ammunition, 155-mm ammunition and 84-mm rocket launcher and ammunition are some of the notable examples.

Of late, the OFB has redefined its role and is in the process of strengthening R & D infrastructure to develop new products, if required, by synergy with technologically advanced weapon manufacturing industries around the globe. The aim is to provide state-of-the-art products, hitherto being imported to the Armed Forces and to increase the share in the overseas market.

The value of production aggregated to Rs. 7086.49 crore in 1999-2000 from Rs. 5441.12 crore achieved during 1998-99 thereby registering a growth of 30.24 per cent.

The Ordnance Factories also improved capacity utilisation and the total turn over; and as such generated a net budget surplus of Rs. 830.16 crore during 1999-2000. There was an overall reduction in various types of inventory held viz. stock holdings of input materials, work in progress and finished stock. However, production of 69 items out of 364 items for which demand existed and target were fixed was behind schedule. The short fall in production was mainly due to non-finalisation of design or non-availability of bulk production clearance etc. In financial terms, the value of the short fall items was less than 10 per cent of the total turn over. Audit have also pointed out some cases of accounting lapses. Necessary action is being taken by Ordnance Factory Organisation to avoid recurrence of such lapses in consultation with their Associate Finance.

The OFB has formulated a perspective plan for modernising infrastructure to develop state-of-the-art products and production technology needed for manufacturing new equipment for induction in the Armed Forces at a short notice. During the IXth Plan, Rs 1,062 crore was invested on modernisation. An investment of Rs 1,786 crore has been earmarked during the ongoing Xth Plan (2002-07).

Capacity utilisation in the Ordnance Factories primarily depends on the actual annual demand from the Armed Forces. The quest for full exploitation of installed capacity, especially during peacetime, and to economise the cost of products propels the Ordnance Factories to diversify their product profile and to broaden the customer base.

The growth in turnover in the non-defence sector in the period 2001-2004 was 75 per cent. During the same period, the value of exports also increased to Rs 63 crore from Rs 4.83 crores in 1999-2000. The Mine Proof Vehicles (MPV) developed by in-house R&D was one of the notable products to be exported. The OFB showcased the indigenously developed 155-mm gun system at an exposition in Abu Dhabi in 2002. The gun has been widely acclaimed. Enquiries have come from many quarters for its purchase.

Many of the factories dealing with explosives and lethal ammunition have also been set up in remote areas for their development. Ordnance Factory estates have been built to provide residential facilities to the employees and their families. Each estate is a self-contained unit having neat and clean housing, market complex, hospital, community centre, sports stadium, schools, post offices, banks and clubs. Trees have been planted on a massive scale to protect the environment. These estates reflect India’s unity in diversity.

A Brief History

Prvi Partizan

Milosa Obrenovica 2

31000 Uzice

SERBIA AND MONTENEGRO

Phone: +381 31 511 382

Fax: +318 31 515 350

e-mail: ppnp@neobee.net

From Website:

History:

Prvi Partizan company was founded in 1928. In those days it was operating under the name FOMU - Arms and Ammunition Factory Uzice. A production program was based on hunting arms and ammunition production in calibers 12, 16 and 20.

The factory had developed pistol and revolver ammunition production by the year 1938. in calibers: 6.35mm, 7.65mm and 9mm Browning; 5.8mm Velodog; 8mm Gasser; 8mm and 9mm Steyr; 7.62mm Nagant; 9mm, 11.2mm and 12 mm Central; and since 1940. rifle ammunition in caliber 7.9 has been produced.

A Brief History

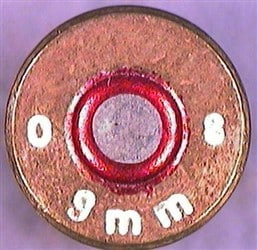

Oman Munition Production Company (OMPC) is the only ammunition factory located in the Sultanate of Oman. It is a government enterprise established in 2014 and aims to provide high quality product requirements for small arms ammunition to the defense and military sector. They conduct research in cooperation with national and international research centers for the development in (SAA) Small Arms Ammunition field. The company collaborates with local and international private sectors to establish SME’s and downstream businesses in Oman and to assist Small Arms Ammunition manufacturing support.

Information taken from website: https://ompc.om/products/

Cartridge cases have lot number laser engraved in extractor groove.

Contact information:

sales@ompc.om

Luzugh-Sumail P.O Box 178 ,PC 615 Sultanate of Oman

A Brief History

Produced by Ozkursan Ammunition out of Bağcılar, Istanbul, Turkey. They have been producing ammunition since 1993, and in 2011 added shotgun cartridges as a product. Other products include blanks and various pistol caliber ammunition. Consumers of their cartridges include the Turkish state institution MKE Machine Chemistry Industry, in addition to exporting to many other countries.

Contact information: