Headstamp Guide - Rimfire

Rimfire Headstamps

A Brief History

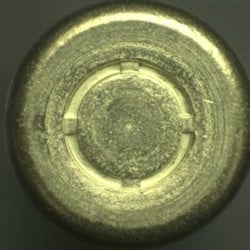

Punch brand, marketed by Federal for personal defense. Has a nickel-plated lead core bullet with flat nose.

https://www.federalpremium.com/rimfire/personal-defense-punch-rimfire/11-PD22L1.html

A Brief History

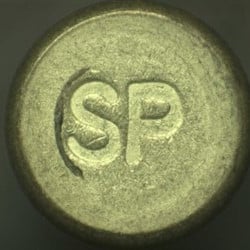

Herter's brand ammunition, which could most likely be made by Winchester or Remington and sold at Cabela's or Bass Pro Shops.This headstamp has also been seen on 22 Long Rifle caliber cartridges sold by Hornady.

A Brief History

Aguila Ammunition

KM6 Carretera A Tepoztlan, Apdo Postal 542

Cuernavaca, MRLS Mexico 62180

Phone: 011-52-777-382-14-02

Fax: 011-52-777-382-14-02

Importer:

CENTURION ORDNANCE, INC.

11614 Rainbow Ridge

Helotes, Texas 78023

Phone: (210) 695-4602

FAX: (210) 695-4603

Aguila Ammunition Website

From Website:

A Brief History

With renowned quality in the national and international markets since 1961. TECNOS manufactures and markets sport shotgun shells, .22 rimfire and centerfire ammunition for the demanding domestic and international markets, including the United States. This worldwide presence is due to our widely qualified personnel and the most technologically advanced equipment, plus a strict quality control of our products. The selection and approval of our raw materials and the various tests of velocity, pressure, accuracy and functionality, permit the production of a totally dependable product. All this is carried out in state of the art chemistry and ballistic laboratories.

Aguila cartridges are exported to various countries, where they have great acceptance and demand due to their excellent international standards of manufacturing such as SAAMI and CIP.

We currently operate three modern and efficient production lines for .22 rimfire cartridges (including blanks and industrial), shotshells, 12 ga., 16 ga., 20 ga., 410 and industrial 8 ga., and centerfire ammunition in calibers such as the new IQ line, 9mm Luger, .380 ACP, .38 Spl., and many others.

A Brief History

Aguila Ammunition

KM6 Carretera A Tepoztlan, Apdo Postal 542

Cuernavaca, MRLS Mexico 62180

Phone: 011-52-777-382-14-02

Fax: 011-52-777-382-14-02

Importer:

CENTURION ORDNANCE, INC.

11614 Rainbow Ridge

Helotes, Texas 78023

Phone: (210) 695-4602

FAX: (210) 695-4603

Aguila Ammunition Website

From Website:

A Brief History

With renowned quality in the national and international markets since 1961. TECNOS manufactures and markets sport shotgun shells, .22 rimfire and centerfire ammunition for the demanding domestic and international markets, including the United States. This worldwide presence is due to our widely qualified personnel and the most technologically advanced equipment, plus a strict quality control of our products. The selection and approval of our raw materials and the various tests of velocity, pressure, accuracy and functionality, permit the production of a totally dependable product. All this is carried out in state of the art chemistry and ballistic laboratories.

Aguila cartridges are exported to various countries, where they have great acceptance and demand due to their excellent international standards of manufacturing such as SAAMI and CIP.

We currently operate three modern and efficient production lines for .22 rimfire cartridges (including blanks and industrial), shotshells, 12 ga., 16 ga., 20 ga., 410 and industrial 8 ga., and centerfire ammunition in calibers such as the new IQ line, 9mm Luger, .380 ACP, .38 Spl., and many others.

A Brief History

RUAG Ammotec GmbH

Kronacher Strasse 63

90765 Fürth

Deutschland

RWS Website

From Website:

RWS stands for the Rheinisch-Westfälischen Sprengstoff factories, which became part of Dynamit Nobel in 1931. RWS rifle cartridges have conquered the world since their introduction to the market and are appreciated by hunters just as much as by sport shooters. Numerous Olympic winners prove the excellent quality of RWS ammunition, which is trusted by many well-known and competent top shooters.

A Brief History

Federal Cartridge Company

900 Ehlen Drive

Anoka, MN 55303-7503

1-800-322-2342

Fax: (763) 323-2506

Federal Cartridge Contact Form

Federal Cartridge Website

From Federal Cartridge Company Website:

Federal Cartridge Company

The Ammunition Industry's Technology Leader

Highlights:

*Federal is a wholly-owned subsidiary of Edina, Minnesota-based ATK

*Federal manufactures a complete line of shotshell, centerfire and rimfire ammunition and components

*Nearly 1,000 employees work at the Anoka, Minnesota facility

*The facility is located on 175 acres in Anoka County and spans the border of Anoka and Coon Rapids with half a million square feet of manufacturing space

*Federal Premium® Ammunition is the company's flagship brand and focuses its competitive advantage on cutting edge technology

ATK Website

From ATK Website:

Our History

ATK was launched as an independent company in 1990, when Honeywell spun off its defense businesses to shareholders. The former Honeywell businesses had supplied defense products and systems to the U.S. and its allies for 50 years, including the first electronic autopilot that enabled B-17 aircraft to accomplish pinpoint bombing missions during World War II.

ATK expanded into the aerospace market with the acquisitions of Hercules Aerospace Company in 1995 and Thiokol Propulsion in 2001, which transformed the company into the world's largest supplier of solid propellant rocket motors and a leading provider of high-performance composite structures.

A series of other acquisitions and key contract wins have continued to increase the company's presence in the aerospace, defense, and commercial ammunition markets:

•2000 Selected to operate Lake City Army Ammunition Plant, the U.S. Government's only small-caliber ammunition manufacturing facility.

•2001 Acquired the commercial ammunition businesses of Blount International, which made ATK the nation's largest manufacturer of ammunition.

•2002 Acquired the ordnance business of Boeing, which brought together ATK's munitions portfolio with the products and capabilities of a leading military gun manufacturer.

•2002 Acquired the assets of Science and Applied Technology, Inc., which added critical precision seeker, guidance, and system-level expertise.

•2003 Acquired Composite Optics, Inc., which made ATK the world leader in composite space structures.

•2003 Acquired GASL and Micro Craft, which added leading-edge propulsion and airframe technologies for highly demanding aerospace and defense applications.

•2004 Acquired Mission Research Corporation, which enabled an advanced aerospace and defense technology pipeline spanning concept development to full-scale production.

•2004 Acquired the PSI Group, which strengthened ATK's space systems portfolio and positioned the company to capture emerging opportunities in spacecraft integration and satellite technology.

•2007 Acquired Swales Aerospace, adding enhanced systems engineering and engineering services to ATKs existing space launch, space exploration, small satellite, and spacecraft markets.

•2009 Acquired Eagle Industries as a wholly-owned subsidiary, expanding position in the domestic and international accessories markets serving military and law enforcement customers.

A Brief History

American Tactical Imports

Marketed under the brand name "Scorpion Ammunition" and available in .22 Magnum.

A Brief History

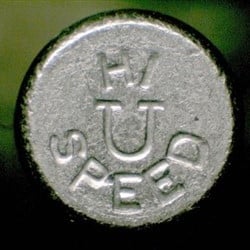

Powder-actuated fasteners for direct fastening tools.

http://bpfasteners.com/product-category/direct-fastening/powder-actuated/powder-loads/

A Brief History

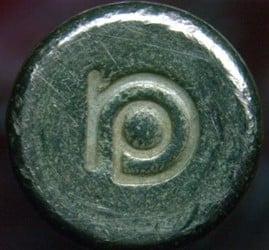

This headstamp is seen on many Browning ammunition products, as it is their signature "Buckmark". Rimfire headstamp seen on the Browning Performance Rimfire (BPR) line.

https://browningammo.com/ammo-detail.html?ammo=Rimfire&category=Hunting

A Brief History

2299 Snake River Ave.

Lewiston, ID 83501

Phone: (208)-799-3944

Fax: (208)-798-3397

From Website:

A History of CCI®

Richard ”Dick” Speer (1915-1994) possessed a remarkable talent for things mechanical. He was a machinist at Boeing Aircraft's Seattle plant when his realized that his brother Vernon's success in the component bullet business meant there was money to be made in reloading.

The brothers found another niche that they felt held opportunity. There were a number of proprietary rifle cartridge like the Weatherby and Newton designs that were not supported by the ”big” ammo companies. Dick decided to make cases to service this small but active market. He left Seattle and joined Vernon in Lewiston, Idaho. In a small room at the Speer bullet plant, he began production of these special cases using an impact extrusion process.

Speer's cases were first sold under the name, "Forged from Solid", before changing it to Speer Cartridge Works. Later, market confusion over to companies with ”Speer” in the name led Dick and his partner Arvid Nelson to change the name to Cascade Cartridges, Inc., or CCI.

Although Dick's case-making process was sound, the quality of the raw material was not. In the early post-war years, most stocks of cartridge brass had been depleted for the war effort. Faced with an untenable situation, Dick turned to a different path.

Component primers for reloaders were in short supply. Some war surplus primers were showing up but the supply and choice was limited. Dick decided to get into the component primer business. He found a refugee scientist from Lithuania, Dr. Victor Jasaitis, and brought him to Lewiston in 1951. Dr. Jasaitis, or "Doc" to most people, was a specialist in explosive chemistry, and developed the exotic chemicals and processes needed for primer manufacture. Although Dick intended to build primers for hobby reloaders, his first shipment was to fulfill an military contract, using the chlorate FA-70 formula. Then he turned to non-corrosive, non-mercuric formulas for sporting cartridges, and reloaders now had a steady supply of rifle and pistol primers that was unheard of previously.

To handle the new business, Dick Speer bought a 17-acre chicken "ranch" next to the Lewiston Gun Club just a mile south of brother Vernon's bullet works. The farmhouse doubled as an office and warehouse, and production began in a renovated chicken coop. He quickly erected modern labs and manufacturing buikdings, gaining him room to expand the product line. When the gun club moved, Dick bought the adjoining property for future expansion. The CCI plant still occupies that property today.

In 1957, Dick added shotshells to the line and, two years later, began making industrial powerloads for powder-actuated fastener systems. In 1962, he expanded into rimfire ammunition with Mini-Mag, still our most popular rimfire product.

In 1967, an Oregon firm, Omark Industries, was seeking an in-house source of loads for the powder-actuated tools they manufactured, and bought CCI from Dick Speer. Seeing the profitability of sporting ammo and components, they wisely elected to let CCI continue to grow in this area. New products such as Stinger, the world's first hypervelocity 22 Long Rifle ammo, rolled out of the CCI facility.

In 1980, CCI entered the centerfire ammunition market with Blazer®. This innovative products used aluminum cartridge cases and high-tech manufacturing processes to create effective, low-cost ammunition for training and practice.

In 1986, CCI's development engineers set out on a comprehensive primer improvement program to meet the requirements of progressive loading equipment that was starting to dominate the reloading market. The program wrapped up in 1989 with the introduction of all-new primers that featured smooth feeding through automated equipment, reduced residue in non-magnum primers, improved primer seating, and better sensitivity that included a larger "sweet spot" for firearms that produced off-center firing pin strikes.

In 1991, CCI opened a new, state-of-the-art primer manufacturing facility to insure that we could supply all our customers' needs. During the so-called "primer shortage" of 1993-94, CCI was the only US primer manufacture to continuously ship primers to commercial accounts, largely due to the increased capacity afforded by this new facility. CCI is also a major supplier of military cannon primers.

In 1990, CCI perfected the first hypervelocity 22 Magnum Rimfire cartridge, and has continued to add new rimfire products like Mini-Mag™ Silhouette, Quik-Shok, and Velocitor™, the fastest 40 grain 22 Long Rifle load on the market.

A Brief History Of CCI® Blazer® Centerfire Ammunition

Including some Frequently Asked Questions

In the late 1970's, US ammunition makers were faced with increasing costs and competition from cheap imports. At CCI-Speer, our premium Lawman® ammunition with high-performance bullets appealed to serious sport shooters and peace officers, but was more than the casual shooter needed. We set out to find a way to offer these shooters economical ammunition that could be priced lower than many imports yet provide American-made quality. As the 38 Special was the most popular handgun cartridge then, the project was known internally as "Low-cost 38's."

We knew that the cartridge case was the single most expensive component of a modern cartridge. Significant costs savings in the other components were not realistic, so we investigated ways that would take costs out of the case without compromising safety or function. The areas of raw material, production processes, labor, and scrap rates all had to be considered.

Raw material costs vary through the year with supply and demand, but we could take cost out of a case by investigating materials other than cartridge brass. We looked at other grades of brass, several classes of polymer plastics, steel, various grades of aluminum, and other materials. Of these, the best candidate was an aircraft-grade aluminum that could be heat-treated for strength. Although cartridge brass and this grade of aluminum cost about the same per pound, one pound of aluminum yields more cases than one pound of brass. We had a material-now the question was, "Can we build cases at a decent internal cost?"

To do this, it meant having a good process and controlling scrap rates. We found the equipment needed to form and heat-treat aluminum cases. We sourced a raw material format that reduced scrap rates from the 30 percent of conventional case forming to a tiny two percent. Over the period of a year, scrap rate improvement alone would yield impressive savings.

We entered this project targeting the 75 percent of the shooting market that does not reload, so several aspects of an aluminum case that affected reloadability played well with a cartridge for the non-reloader. To discourage reloading of Blazer cases, and to gain a small savings on primer cost, we elected to go with efficient Berdan priming. In the Berdan system, the anvil moves from the primer to the case. Adding a Berdan anvil to a case is free; in a Boxer primer it is a separate part with its own cost.

Original Blazer cases used an odd primer diameter (0.195 inch) to further discourage reloading. This was eventually changed when we started loading higher pressure cartridges like the 9mm Luger and 357 Magnum. They needed the extra material in the case head that a 0.175 inch primer pocket affords. From that point on, we used a standard .175 inch Berdan pocket in all cartridges that took a small pistol primer.

An early problem came up. Although cases were heat-treated "by the book," they were not springing away from revolver chamber walls as they should. We discovered the problem was "the book," not the material. All published aluminum heat treat references were prepared with large part like landing gear struts in mind. The techniques did not translate to small parts. Out of necessity, CCI rewrote the book on aluminum heat treatment. We made numerous breakthroughs in this field that gave us a strong case and a leadership position in this technology.

The final case was ready for market. The savings were partially due to getting more cases per pound of raw material, but the savings in processing and the all-important scrap rate were as significant. The economical case was a multi-discipline success that grew directly out of smart engineering.

The cases were done, and a new, more efficient loading line was built to reduce direct labor costs and increase throughput. The later had a remarkable positive effect on the bottom line. We went "outside the box" to develop a loading system that was not previously used for centerfire ammunition. It was safe, efficient, and enabled us to change caliber set-ups easily to quickly react to incoming orders. In 1981, the first Blazer ammunition was introduced to the market. It was 38 Special, loaded with a 158 grain round nose lead bullet. Blazer was on it way.

Today, Blazer is a highly evolved product. Through constant testing and improvement, we have overcome the objections that traditional shooters found to a non-brass cartridge case. The number of Blazer calibers increased to 13 today. We offer a selection of bullet weights and types not found in most imports or "white box" domestic ammo.

A Brief History

Headstamp found exclusively on CCI A17 Varmint Tip 17HMR ammunition. This product was designed around the Savage Arms A-17 semi-automatic rifle for optimized feeding.

https://www.cci-ammunition.com/rimfire/cci/a17/6-949CC.html

CCI Ammunition

2299 Snake River Ave.

Lewiston, ID 83501

800-948-1356

A Brief History

Seen on Cascade Ammo brand from CCI out of Mexico. Their typical headstamps are "Ci" but this one was introduced in 2019 for their 60th anniversary. Other products sold include shotgun shells and several centerfire handgun cartridges.

This particular information has not been verified with a distributor or manufacturer at this time.

Contact information:

info@cartuchosci.com

A Brief History

2299 Snake River Ave.

Lewiston, ID 83501

Phone: (208)-799-3944

Fax: (208)-798-3397

From Website:

A History of CCI®

Richard ”Dick” Speer (1915-1994) possessed a remarkable talent for things mechanical. He was a machinist at Boeing Aircraft's Seattle plant when his realized that his brother Vernon's success in the component bullet business meant there was money to be made in reloading.

The brothers found another niche that they felt held opportunity. There were a number of proprietary rifle cartridge like the Weatherby and Newton designs that were not supported by the ”big” ammo companies. Dick decided to make cases to service this small but active market. He left Seattle and joined Vernon in Lewiston, Idaho. In a small room at the Speer bullet plant, he began production of these special cases using an impact extrusion process.

Speer's cases were first sold under the name, "Forged from Solid", before changing it to Speer Cartridge Works. Later, market confusion over to companies with ”Speer” in the name led Dick and his partner Arvid Nelson to change the name to Cascade Cartridges, Inc., or CCI.

Although Dick's case-making process was sound, the quality of the raw material was not. In the early post-war years, most stocks of cartridge brass had been depleted for the war effort. Faced with an untenable situation, Dick turned to a different path.

Component primers for reloaders were in short supply. Some war surplus primers were showing up but the supply and choice was limited. Dick decided to get into the component primer business. He found a refugee scientist from Lithuania, Dr. Victor Jasaitis, and brought him to Lewiston in 1951. Dr. Jasaitis, or "Doc" to most people, was a specialist in explosive chemistry, and developed the exotic chemicals and processes needed for primer manufacture. Although Dick intended to build primers for hobby reloaders, his first shipment was to fulfill an military contract, using the chlorate FA-70 formula. Then he turned to non-corrosive, non-mercuric formulas for sporting cartridges, and reloaders now had a steady supply of rifle and pistol primers that was unheard of previously.

To handle the new business, Dick Speer bought a 17-acre chicken "ranch" next to the Lewiston Gun Club just a mile south of brother Vernon's bullet works. The farmhouse doubled as an office and warehouse, and production began in a renovated chicken coop. He quickly erected modern labs and manufacturing buikdings, gaining him room to expand the product line. When the gun club moved, Dick bought the adjoining property for future expansion. The CCI plant still occupies that property today.

In 1957, Dick added shotshells to the line and, two years later, began making industrial powerloads for powder-actuated fastener systems. In 1962, he expanded into rimfire ammunition with Mini-Mag, still our most popular rimfire product.

In 1967, an Oregon firm, Omark Industries, was seeking an in-house source of loads for the powder-actuated tools they manufactured, and bought CCI from Dick Speer. Seeing the profitability of sporting ammo and components, they wisely elected to let CCI continue to grow in this area. New products such as Stinger, the world's first hypervelocity 22 Long Rifle ammo, rolled out of the CCI facility.

In 1980, CCI entered the centerfire ammunition market with Blazer®. This innovative products used aluminum cartridge cases and high-tech manufacturing processes to create effective, low-cost ammunition for training and practice.

In 1986, CCI's development engineers set out on a comprehensive primer improvement program to meet the requirements of progressive loading equipment that was starting to dominate the reloading market. The program wrapped up in 1989 with the introduction of all-new primers that featured smooth feeding through automated equipment, reduced residue in non-magnum primers, improved primer seating, and better sensitivity that included a larger "sweet spot" for firearms that produced off-center firing pin strikes.

In 1991, CCI opened a new, state-of-the-art primer manufacturing facility to insure that we could supply all our customers' needs. During the so-called "primer shortage" of 1993-94, CCI was the only US primer manufacture to continuously ship primers to commercial accounts, largely due to the increased capacity afforded by this new facility. CCI is also a major supplier of military cannon primers.

In 1990, CCI perfected the first hypervelocity 22 Magnum Rimfire cartridge, and has continued to add new rimfire products like Mini-Mag™ Silhouette, Quik-Shok, and Velocitor™, the fastest 40 grain 22 Long Rifle load on the market.

A Brief History Of CCI® Blazer® Centerfire Ammunition

Including some Frequently Asked Questions

In the late 1970's, US ammunition makers were faced with increasing costs and competition from cheap imports. At CCI-Speer, our premium Lawman® ammunition with high-performance bullets appealed to serious sport shooters and peace officers, but was more than the casual shooter needed. We set out to find a way to offer these shooters economical ammunition that could be priced lower than many imports yet provide American-made quality. As the 38 Special was the most popular handgun cartridge then, the project was known internally as "Low-cost 38's."

We knew that the cartridge case was the single most expensive component of a modern cartridge. Significant costs savings in the other components were not realistic, so we investigated ways that would take costs out of the case without compromising safety or function. The areas of raw material, production processes, labor, and scrap rates all had to be considered.

Raw material costs vary through the year with supply and demand, but we could take cost out of a case by investigating materials other than cartridge brass. We looked at other grades of brass, several classes of polymer plastics, steel, various grades of aluminum, and other materials. Of these, the best candidate was an aircraft-grade aluminum that could be heat-treated for strength. Although cartridge brass and this grade of aluminum cost about the same per pound, one pound of aluminum yields more cases than one pound of brass. We had a material-now the question was, "Can we build cases at a decent internal cost?"

To do this, it meant having a good process and controlling scrap rates. We found the equipment needed to form and heat-treat aluminum cases. We sourced a raw material format that reduced scrap rates from the 30 percent of conventional case forming to a tiny two percent. Over the period of a year, scrap rate improvement alone would yield impressive savings.

We entered this project targeting the 75 percent of the shooting market that does not reload, so several aspects of an aluminum case that affected reloadability played well with a cartridge for the non-reloader. To discourage reloading of Blazer cases, and to gain a small savings on primer cost, we elected to go with efficient Berdan priming. In the Berdan system, the anvil moves from the primer to the case. Adding a Berdan anvil to a case is free; in a Boxer primer it is a separate part with its own cost.

Original Blazer cases used an odd primer diameter (0.195 inch) to further discourage reloading. This was eventually changed when we started loading higher pressure cartridges like the 9mm Luger and 357 Magnum. They needed the extra material in the case head that a 0.175 inch primer pocket affords. From that point on, we used a standard .175 inch Berdan pocket in all cartridges that took a small pistol primer.

An early problem came up. Although cases were heat-treated "by the book," they were not springing away from revolver chamber walls as they should. We discovered the problem was "the book," not the material. All published aluminum heat treat references were prepared with large part like landing gear struts in mind. The techniques did not translate to small parts. Out of necessity, CCI rewrote the book on aluminum heat treatment. We made numerous breakthroughs in this field that gave us a strong case and a leadership position in this technology.

The final case was ready for market. The savings were partially due to getting more cases per pound of raw material, but the savings in processing and the all-important scrap rate were as significant. The economical case was a multi-discipline success that grew directly out of smart engineering.

The cases were done, and a new, more efficient loading line was built to reduce direct labor costs and increase throughput. The later had a remarkable positive effect on the bottom line. We went "outside the box" to develop a loading system that was not previously used for centerfire ammunition. It was safe, efficient, and enabled us to change caliber set-ups easily to quickly react to incoming orders. In 1981, the first Blazer ammunition was introduced to the market. It was 38 Special, loaded with a 158 grain round nose lead bullet. Blazer was on it way.

Today, Blazer is a highly evolved product. Through constant testing and improvement, we have overcome the objections that traditional shooters found to a non-brass cartridge case. The number of Blazer calibers increased to 13 today. We offer a selection of bullet weights and types not found in most imports or "white box" domestic ammo.

A Brief History

Essay from "Industrial Canada" 1967

CANADIAN INDUSTRIES LIMITED

The corporate history of Canadian Industries Limited began in 1862. In that year, the Hamilton Powder Company was incorporated and acquired the Canada Powder Company (started in 1852). Their product was the black blasting powder so essential to Canada's pioneers.

In 1878 the company was purchased by Dr. Thomas C. Brainerd, a U.S. businessman well-known in the powder-making industry. To meet the need for tremendous quantities of explosives (especially nitro-glycerine dynamite) required for construction of the Canadian Pacific Railway, a dynamite plant was built at McMasterville, Que. on the general site of the present plant. Other black powder plants were acquired in Quebec and the Maritimes and, in 1890, the Hamilton Powder Company established the first explosives plant in the far west near Nanaimo, B.C.

Another C-I-L ancestor, the Dominion Cartridge Company, was founded at Brownsburg, Que. in 1886 by Captain A. L. ("Gat") Howard, who introduced the Gatling gun into Canada and operated a battery of two of the new weapons during the Riel Rebellion. Howard won the support of several influential Canadians, including Dr. T. C. Brainerd of Hamilton Powder, and when the Dominion Cartridge Company was formed Dr. Brainerd became its first president, with "Gat" Howard as plant manager.

In 1910 five explosives companies, a cartridge plant and a plant making acids and fertilizers merged to form Canadian Explosives Limited. Hamilton Powder Company and the Dominion Cartridge Company were among them; the others were Acadia Powder Company, Waverley, N.S., Ontario Powder Company, Tweed, Ont., Standard Explosives Company, Vaudreuil, Que., Western Explosives Company, near Vancouver and the Victoria Chemical Company, Victoria, B.C.

Throughout the 20's, Canadian Explosives Limited diversified into paint and varnish, coated fabrics and plastics. In 1927 the company's name was changed to Canadian Industries Limited.

At the outbreak of World War II C-I-L put its technological experience at the service of the Canadian government. A wholly-owned subsidiary, Defence Industries Limited, was formed to handle the construction, operation and management of Crown-owned munitions plants. Defence Industries Limited designed, built and operated Crown-owned plants worth more than $100 million, and at one time employed 33,000 men and women.

A great post-war building program geared C-I-L to meet peacetime needs for explosives, paints, agricultural and industrial chemicals, plastics, sporting ammunition and man-made textile fabrics.

In 1954 C-I-L was divided into two separate companies in accordance with the ruling of a U.S. court which had ordered E. I. du Pont de Nemours & Company to end its joint interests with Imperial Chemicals Limited.

Today the company is the largest producer of chemicals and related products in Canada. With head office in Montreal, 36 plants across Canada and sales offices and warehouses in most of the major centres, C-I-L handles hundreds of products manufactured in its own plants and those of its associated companies.

The company also has manufacturing interests in the West Indies, Liberia and Mexico.

A Brief History

From Winchester Website:

During the late 1890s and early 1900s, several companies in the United States began to develop as integrated ammunition organizations.

One of those was the Western Cartridge Company, which was also a powder manufacturer. In 1892, Franklin W. Olin and his associates formed the Equitable Powder Manufacturing Company at East Alton, Illinois, to manufacture black powder that was sold chiefly to the mines in the area. However, because that business was seasonal, Olin became interested in loading shotshells. In February 1898, he persuaded his associates to join him in forming the Western Cartridge Company, also located in East Alton, the principal purpose being to provide a market for powder that could be produced by The Equitable Powder Company in the off season.

With the outbreak of World War I, interest in negotiating contracts for arms and ammunition picked up sharply. When the United States declared war in 1917, Winchester again was called on to fulfill contracts for arms and ammunition.

The purchase of Winchester by the Olin interests brought a breath of life to the institution. A major benefit was having the leadership of John M. Olin, son of company founder F.W. Olin. When John Olin, at that time First Vice President of Western Cartridge Company, came to New Haven to find out just what he and his associates had purchased, he found stored-up accumulation of new gun models and ideas. He was able to make an accurate appraisal of each model and to introduce a number of revolutionary ideas he had in mind.

John Olin was a master inventor

...and his name appeared on more than 20 patents, several of which dealt with Super-X developments. Super-X ammunition, probably Western Cartridge Company's most widely known product, resulted from his work during World War I. Super-X was a major development in the ammunition industry early in the post-war years. It came, according to John Olin himself, partly from his personal desire to teach sportsmanship to a hunter who shot ducks on the water rather than on the wing. Olin even suggested to the greedy hunter that if he needed meat on the table he should go shoot a cow. "You can get a thousand pounds of meat with one shell."

On December 14, 1940, a contract was signed with the government for the United States Cartridge Company, a subsidiary corporation of the Olin-owned companies, to build and operate the St. Louis Ordnance Plant, the greatest small arms plant in the military history of the nation. At its peak production period in 1943 the plant had 34,338 employees on its payroll. Manufacture of ammunition components began October 20, 1941, and the first finished ammunition came off the line at the new plant on December 8, 1941, the day after the Japanese attack on Pearl Harbor forced the United States into World War II.

Total production of .30 and .50 caliber rifle and machine gun ammunition at the St. Louis Ordnance Plant during the war, 6,738,009,746 loaded rounds, exceeded the output of all of the nation's small arms ammunition plants in World War I. In addition, the Western Cartridge Company plant at East Alton produced 4,022,621,734 loaded rounds of ammunition, and the Winchester plant in New Haven another 4,499,493,774 rounds. Thus a total of 15,260,125,254 rounds of ammunition were produced by the various Olin companies during World War II.

A Brief History

Sovereign is made in Mexico by Industrias Tecnos S.A. de C.V. Distributed in the US by Southern Gun Distributors, Opa-Locka, FL.

[i]unconfirmed[/i]:

The story is that Southern Gun Distributors of Opa-Locka, Florida in 1985 ordered a large quantity of .22 LR H.V.; .22 LR H.V.; H.P., .22 L.R. Standard Velocity and .22 Shorts. Southern Gun sent the artwork for the boxes to Mexico. The buyer for Southern Gun was D. Zook. He received a call from Mexico and was told with an order of this size they could have their own headstamp. What headstamp did they want? Zook asked what was a headstamp. He was told letters. Not knowing anything else he supplied his initials "DZ".

(from http://www.iaaforum.org/forum3/viewtopic.php?f=1&t=3113)

A Brief History

Fiocchi Ammunition USA

6930 Fremont Road

Ozark, MO 65721

Phone: 417-725-4118

Fax: 417-725-1039

Fiocchi USA Website

From Website (Translated):

Fiocchi activity starts in 1876 when the founder, Giulio Fiocchi, took over a small factory producing black powder. At that time a radical change was introduced in firearms: the newly developed breech-loader employing ammunition and components (especially cases) of modern concept replaced the traditional muzzle loader.

Fiocchi took the chance and started manufacturing cases with primers suitable for reloading; in the early 90's the production is extended to complete cartridges

loaded with bullets or shots.

At the same time Fiocchi gave up the production of black powder as it was no more profitable.

Since the very beginning of its activity the company adopted a structure policy laying the ground for then and today's succes: production machinery and equipment are designed and made by Fiocchi fully meeting its production

requirements.

Such a strategy has always enabled Fiocchi to guide production with up-to-date technology matching with its manufacturing configuration.

At the beginning of 20th century Fiocchi introduced a product diversification and successfully entered a new field of activity-snaps-made using the off-cuts of production.

Snaps busines assumed an important role to counterbalance

the trend of the ammunition market and at the end of 80's was so attractive that, upon Fiocchi decision to focus ammunition as core business, the snaps factory was taken over by the European leader in this field of activity.

During its long life Fiocchi has manufactured all kind of ammunition for guns rifle or pistol: from fire pin shotshells and cartridges, to all kind of cartridges and cases either rimfire or centerfire.

Nowadays Fiocchi is world-leader in small gauge ammunition and offers a very wide range of products suitable to meet all demands from shooters or hunters.

Qualifications and Certifications of prestige attest the level of quality achieved by the company.

Fiocchi history

1876 Year of foundation

1877 Start of ammunition production

1901 Product diversification: snaps

1930 Beginning of export

1940 Development of social policy in the territory of Lecco

1945 Bombing of the plant in Lecco

1946 Re-building of the plant

1970 Attack on the European markets

1980 Start of .22 Super Match production

1985 New quality inspection unit

1985 Start of "leadless" primers production

1989 Nato qualification of the cartridge 9 mm Parabellum

1990 Impulse to world-market

expansion

1990 Quality Sistem Certificate in accordance with the stardands NATO AQAP-1

1991 Start of production of ammuni-

tion with frangible bullets

1993 New loading department for .22 cartridges

1994 New flexible manufacturing line for centerfire ammunition

1994 Automatization line for cases

production

1995 New line of products: "Official" clay shooting cartridges

1996 New line of Spas Mil and Law Enforcement ammunition

1999 New line of hunting cartridges

1999 Nato qualification of the cartridges 5,56 mm Ball

2003 Environment Management System Certificate in accordance with the standards UNI EN ISO 14001:1996

2003 Quality Management System Certificate in accordance with the standards UNI EN ISO 9001:2000

A Brief History

.22 caliber cartridges produced under the name "Federal". Found on both American Eagle and Federal brand ammo.

A Brief History

22 Long Rifle Special Winchester Boy Scout, 75th. Anniversary Cartridge (Nickle Plated Case)

Submitted by Bill Wheatley

A Brief History

Gemtech's subsonic silencer ammunition.

From their website: (click here for Gemtech's website)

"After years of recommending various brands and types of ammunition, we decided to do things right and create our own optimized round for suppressor useage. Putting together a heavier bullet, a cleaner powder, a premium lube on the lead round nose projectile gave us consistent velocities and harder hitting performance at subsonic, suppressor-friendly speed. The 42 grain lead round nose bullet is heavier than traditionally available rounds, but isn't so heavy as to cause instability. While "harder hitting" and ."22lr" aren't usually associated together, steel silhouette shooters will appreciate the difference between a knockdown and a wobbling target that stays up! A designed velocity of 1020 feet per second ensures the heavier projectile remains subsonic speed in most all firearms without resorting to anemic velocities.

A Brief History

Fiocchi Ammunition USA

6930 Fremont Road

Ozark, MO 65721

Phone: 417-725-4118

Fax: 417-725-1039

Fiocchi USA Website

From Website (Translated):

Fiocchi activity starts in 1876 when the founder, Giulio Fiocchi, took over a small factory producing black powder. At that time a radical change was introduced in firearms: the newly developed breech-loader employing ammunition and components (especially cases) of modern concept replaced the traditional muzzle loader.

Fiocchi took the chance and started manufacturing cases with primers suitable for reloading; in the early 90's the production is extended to complete cartridges

loaded with bullets or shots.

At the same time Fiocchi gave up the production of black powder as it was no more profitable.

Since the very beginning of its activity the company adopted a structure policy laying the ground for then and today's succes: production machinery and equipment are designed and made by Fiocchi fully meeting its production

requirements.

Such a strategy has always enabled Fiocchi to guide production with up-to-date technology matching with its manufacturing configuration.

At the beginning of 20th century Fiocchi introduced a product diversification and successfully entered a new field of activity-snaps-made using the off-cuts of production.

Snaps busines assumed an important role to counterbalance

the trend of the ammunition market and at the end of 80's was so attractive that, upon Fiocchi decision to focus ammunition as core business, the snaps factory was taken over by the European leader in this field of activity.

During its long life Fiocchi has manufactured all kind of ammunition for guns rifle or pistol: from fire pin shotshells and cartridges, to all kind of cartridges and cases either rimfire or centerfire.

Nowadays Fiocchi is world-leader in small gauge ammunition and offers a very wide range of products suitable to meet all demands from shooters or hunters.

Qualifications and Certifications of prestige attest the level of quality achieved by the company.

Fiocchi history

1876 Year of foundation

1877 Start of ammunition production

1901 Product diversification: snaps

1930 Beginning of export

1940 Development of social policy in the territory of Lecco

1945 Bombing of the plant in Lecco

1946 Re-building of the plant

1970 Attack on the European markets

1980 Start of .22 Super Match production

1985 New quality inspection unit

1985 Start of "leadless" primers production

1989 Nato qualification of the cartridge 9 mm Parabellum

1990 Impulse to world-market

expansion

1990 Quality Sistem Certificate in accordance with the stardands NATO AQAP-1

1991 Start of production of ammuni-

tion with frangible bullets

1993 New loading department for .22 cartridges

1994 New flexible manufacturing line for centerfire ammunition

1994 Automatization line for cases

production

1995 New line of products: "Official" clay shooting cartridges

1996 New line of Spas Mil and Law Enforcement ammunition

1999 New line of hunting cartridges

1999 Nato qualification of the cartridges 5,56 mm Ball

2003 Environment Management System Certificate in accordance with the standards UNI EN ISO 14001:1996

2003 Quality Management System Certificate in accordance with the standards UNI EN ISO 9001:2000

A Brief History

Hornady Manufacturing Co.

Box 1848

Grand Island, NE 68802

1-800-338-3220

Fax: 308-382-5761

E-mail: webmaster@hornady.com

Hornady Website

From Website:

“Ten bullets through one hole” was the philosophy of Joyce Hornady, the company's founder. This great idea of accuracy and perfection has continued from the first bullet made more than half a century ago, right through today.

Like so many successful companies, Hornady Manufacturing was born out of one man’s vision of a better product for his own use. Joyce Hornady was an ardent shooter and needed a constant supply of good, accurate bullets. While commercially available bullets were usable, Joyce felt that better bullets could be made.

During World War II, Joyce had taken a job in a guard training unit at the Grand Island Arsenal. He and his family of three moved to Grand Island from Lincoln . In the first years following the war, shooters and hunters used some of the vast surplus of military ammunition for their sport shooting. This surplus ammunition, however, did not offer the accuracy or performance needed for target shooting, big game or varmint hunting. Joyce realized the need for better bullets and he responded to it. In 1949, using his training as an engineer, he and his original partner Vernon Speer built a machine that converted spent .22 rimfire cases into bullet jackets, and then into bullets. Advertised in the “American Rifleman” Magazine, these bullets sold well all over the country. Using a surplus bullet assembly press, he also began to produce a 30 caliber bullet. From the initial production in 1949, this bullet still remains one of our most popular.

The early years

The first year yielded total sales of only $10,000 - a figure that increased three-fold over the first decade. The Korean War slowed growth for a time, as raw materials were allocated for war production. During this time, Hornady Manufacturing produced a variety of products not associated with bullets - aluminum hearts for bracelets, and condenser cans for the government. After the war, the can material was used to make ultra thin copper jackets for varmint bullets.

By 1958, the company had moved from the rented garage that was its first home, to our present location on the west edge of Grand Island. The new facility included a 200 yard underground tunnel for test firing new designs and for quality control of bullets in production. A new rifle bullet shape was developed at this time and continues to be used to this day. Also, the number of full-time employees increased to 40.

Since not all hunters and shooters are reloaders, in 1964, Hornady introduced its line of Frontier ammunition, which was manufactured using surplus military brass. The initial offering was five different cartridges. However the Viet Nam war caused a shortage of military brass, so the ammunition began to be loaded with new brass cases.

Steve Hornady

By this time, Steve Hornady had joined the company fulltime. Hornady Manufacturing had become the world's largest independent manufacturer of bullets, and the Frontier ammunition division also continued to prosper. In 1972, Hornady opened a new chapter with the accquisition of the Pacific Tool Company -- a California maker of home reloading presses. Hornady brought Pacific’s manufacturing operation into the Grand Island fold, and brought exciting improvements to the product line.

Through the 1970's the Hornady divisions continued to grow. New bullet designs and ammunition were added to the line as well as different styles of reloading equipment. In the late '70's Hornady acquired the West Coast Shot Company in Reno Nevada , and renamed it Hornady Magnum Shot. It became in independent company in the early 1990's reverting back to its original name, and produces premium grade lead shot.

In January, 1981, Joyce, along with engineer Ed Heers, and customer service manager Jim Garber were killed in a private plane crash en route to New Orleans for a major trade show. Steve Hornady became president, and his sister Margaret Hornady David and her husband Don David moved to Grand Island to become vice-president and chief engineer respectively.

In 1983, Frontier Ammunition and Pacific reloading Tools were renamed Hornady Custom Ammunition and Hornady Reloading Tools to reflect the merger of the divisions into one corporation.

In 1990, the Hornady XTP (which stands for Extreme Terminal Performance) won the industry's Product Award of Merit 1990 from the National Association of Federal Licensed Dealers.

Today

Hornady Manufacturing has over 150 employees, and occupies over 70,000 square feet of a plant that in a single day produces more bullets than the entire first year's production. Our market includes not only the United States , but much of Canada ,Europe ,Australia ,Iceland ,New Zealand , and parts of Africa

We continue to be the largest independent producer of bullets which we sell as separate reloading components, loaded on our Custom Ammunition, and also sell to other ammunition companies to be loaded on their premium grade ammo. Marval Hornady is still active in the company as chairman of the board, and as you're aware, does a huge amount of volunteer work in Grand Island promoting the arts, the Stuhr Museum, and College Park, to name a few.

Our employees exhibit our products at trade shows and shooting matches across the country, and our product lines are represented to dealers and distributors by over 60 independent reps. In spite of the sluggish economy in parts of the country, we've been able to keep two work shifts in both the bullet and tool division and a single shift making ammo.

"Ten bullets through one hole" is still what it takes to make a good product. And thanks to continued advancements in Hornady's engineering designs and production tolerances, that hole keeps getting tighter and tighter.

A Brief History

Federal Cartridge Company

900 Ehlen Drive

Anoka, MN 55303-7503

1-800-322-2342

Fax: (763) 323-2506

Federal Cartridge Contact Form

Federal Cartridge Website

From Federal Cartridge Company Website:

Federal Cartridge Company

The Ammunition Industry's Technology Leader

Highlights:

*Federal is a wholly-owned subsidiary of Edina, Minnesota-based ATK

*Federal manufactures a complete line of shotshell, centerfire and rimfire ammunition and components

*Nearly 1,000 employees work at the Anoka, Minnesota facility

*The facility is located on 175 acres in Anoka County and spans the border of Anoka and Coon Rapids with half a million square feet of manufacturing space

*Federal Premium® Ammunition is the company's flagship brand and focuses its competitive advantage on cutting edge technology

ATK Website

From ATK Website:

Our History

ATK was launched as an independent company in 1990, when Honeywell spun off its defense businesses to shareholders. The former Honeywell businesses had supplied defense products and systems to the U.S. and its allies for 50 years, including the first electronic autopilot that enabled B-17 aircraft to accomplish pinpoint bombing missions during World War II.

ATK expanded into the aerospace market with the acquisitions of Hercules Aerospace Company in 1995 and Thiokol Propulsion in 2001, which transformed the company into the world's largest supplier of solid propellant rocket motors and a leading provider of high-performance composite structures.

A series of other acquisitions and key contract wins have continued to increase the company's presence in the aerospace, defense, and commercial ammunition markets:

•2000 Selected to operate Lake City Army Ammunition Plant, the U.S. Government's only small-caliber ammunition manufacturing facility.

•2001 Acquired the commercial ammunition businesses of Blount International, which made ATK the nation's largest manufacturer of ammunition.

•2002 Acquired the ordnance business of Boeing, which brought together ATK's munitions portfolio with the products and capabilities of a leading military gun manufacturer.

•2002 Acquired the assets of Science and Applied Technology, Inc., which added critical precision seeker, guidance, and system-level expertise.

•2003 Acquired Composite Optics, Inc., which made ATK the world leader in composite space structures.

•2003 Acquired GASL and Micro Craft, which added leading-edge propulsion and airframe technologies for highly demanding aerospace and defense applications.

•2004 Acquired Mission Research Corporation, which enabled an advanced aerospace and defense technology pipeline spanning concept development to full-scale production.

•2004 Acquired the PSI Group, which strengthened ATK's space systems portfolio and positioned the company to capture emerging opportunities in spacecraft integration and satellite technology.

•2007 Acquired Swales Aerospace, adding enhanced systems engineering and engineering services to ATKs existing space launch, space exploration, small satellite, and spacecraft markets.

•2009 Acquired Eagle Industries as a wholly-owned subsidiary, expanding position in the domestic and international accessories markets serving military and law enforcement customers.

A Brief History

Aguila Ammunition

KM6 Carretera A Tepoztlan, Apdo Postal 542

Cuernavaca, MRLS Mexico 62180

Phone: 011-52-777-382-14-02

Fax: 011-52-777-382-14-02

Importer:

CENTURION ORDNANCE, INC.

11614 Rainbow Ridge

Helotes, Texas 78023

Phone: (210) 695-4602

FAX: (210) 695-4603

Aguila Ammunition Website

From Website:

A Brief History

With renowned quality in the national and international markets since 1961. TECNOS manufactures and markets sport shotgun shells, .22 rimfire and centerfire ammunition for the demanding domestic and international markets, including the United States. This worldwide presence is due to our widely qualified personnel and the most technologically advanced equipment, plus a strict quality control of our products. The selection and approval of our raw materials and the various tests of velocity, pressure, accuracy and functionality, permit the production of a totally dependable product. All this is carried out in state of the art chemistry and ballistic laboratories.

Aguila cartridges are exported to various countries, where they have great acceptance and demand due to their excellent international standards of manufacturing such as SAAMI and CIP.

We currently operate three modern and efficient production lines for .22 rimfire cartridges (including blanks and industrial), shotshells, 12 ga., 16 ga., 20 ga., 410 and industrial 8 ga., and centerfire ammunition in calibers such as the new IQ line, 9mm Luger, .380 ACP, .38 Spl., and many others.

A Brief History

Federal Cartridge Company

900 Ehlen Drive

Anoka, MN 55303-7503

1-800-322-2342

Fax: (763) 323-2506

Federal Cartridge Contact Form

Federal Cartridge Website

From Federal Cartridge Company Website:

Federal Cartridge Company

The Ammunition Industry's Technology Leader

Highlights:

*Federal is a wholly-owned subsidiary of Edina, Minnesota-based ATK

*Federal manufactures a complete line of shotshell, centerfire and rimfire ammunition and components

*Nearly 1,000 employees work at the Anoka, Minnesota facility

*The facility is located on 175 acres in Anoka County and spans the border of Anoka and Coon Rapids with half a million square feet of manufacturing space

*Federal Premium® Ammunition is the company's flagship brand and focuses its competitive advantage on cutting edge technology

ATK Website

From ATK Website:

Our History

ATK was launched as an independent company in 1990, when Honeywell spun off its defense businesses to shareholders. The former Honeywell businesses had supplied defense products and systems to the U.S. and its allies for 50 years, including the first electronic autopilot that enabled B-17 aircraft to accomplish pinpoint bombing missions during World War II.

ATK expanded into the aerospace market with the acquisitions of Hercules Aerospace Company in 1995 and Thiokol Propulsion in 2001, which transformed the company into the world's largest supplier of solid propellant rocket motors and a leading provider of high-performance composite structures.

A series of other acquisitions and key contract wins have continued to increase the company's presence in the aerospace, defense, and commercial ammunition markets:

•2000 Selected to operate Lake City Army Ammunition Plant, the U.S. Government's only small-caliber ammunition manufacturing facility.

•2001 Acquired the commercial ammunition businesses of Blount International, which made ATK the nation's largest manufacturer of ammunition.

•2002 Acquired the ordnance business of Boeing, which brought together ATK's munitions portfolio with the products and capabilities of a leading military gun manufacturer.

•2002 Acquired the assets of Science and Applied Technology, Inc., which added critical precision seeker, guidance, and system-level expertise.

•2003 Acquired Composite Optics, Inc., which made ATK the world leader in composite space structures.

•2003 Acquired GASL and Micro Craft, which added leading-edge propulsion and airframe technologies for highly demanding aerospace and defense applications.

•2004 Acquired Mission Research Corporation, which enabled an advanced aerospace and defense technology pipeline spanning concept development to full-scale production.

•2004 Acquired the PSI Group, which strengthened ATK's space systems portfolio and positioned the company to capture emerging opportunities in spacecraft integration and satellite technology.

•2007 Acquired Swales Aerospace, adding enhanced systems engineering and engineering services to ATKs existing space launch, space exploration, small satellite, and spacecraft markets.

•2009 Acquired Eagle Industries as a wholly-owned subsidiary, expanding position in the domestic and international accessories markets serving military and law enforcement customers.

A Brief History

Magtech Ammunition Co., Inc.

6845 20th Avenue South Suite 120

Centerville, MN 55038

Toll Free: 1-800-466-7191

Tel: 651-762-8500

Fax: 651-429-9485

Magtech Website

Companhia Brasileira de Cartuchos

Av. Humberto de Campos 3220

09400 000 Ribeiaro Pires SP

Tel: +55 11 4822 8200

Fax: +55 11 4822 8323

CBC Website

From Website:

CBC Profile

CBC - Companhia Brasileira de Cartuchos is the largest military and commercial ammunition manufacturer in Latin America, and has over 60 years of small caliber military ammunition expertise. The high quality of CBC’s products is commercially recognized internationally under the brand name MAGTECH.

CBC Overview

CBC was founded in 1926 and from 1936 up to 1979, Remington Arms and ICI were the main shareholders. Today it is a totally privately owned Brazilian company and the principal share holder is the ARBI investment group.

CBC employs 1,200 people and produces more than 415 million rounds of ammunition each year. CBC’s manufacturing operations are ISO 9001 certified.

CBC’s main industrial complex is located in the city of Ribeirao Pires in the State of Sao Paulo, Brazil, in a vast green area of 500 acres with 377.000 square feet of built area. This key facility contains its ammunition, propellant powder and primer composition manufacturing operations, as well as its central offices. A second industrial complex, located in the south of Brazil is dedicated to the production of firearms and shot-shells.

All the ammunition lots produced at CBC are evaluated in the ballistic laboratory. Tests are monitored by very precise computers, which check for the ammunition performance, including velocity, pressure, accuracy and impact. All of these facilities are also available for the improvement and development of ammunition for all our customers. All ammunition is tested, from .22RF up to the 20 mm and 30 mm, used in military ships and aircrafts. All the information generated during the testing is automatically entered in the computer databases. Test facilities include six tunnels for ballistic tests, which range from 55 to 492 yards in length.

CBC offers a wide range of products for commercial and military use, including centerfire and rimfire ammunition of small and medium calibers, industrial cartridges, ammunition components, propellant powder, shotguns and rifles. CBC produces cartridges for both the civilian and military markets with calibers ranging from .22LR to 30 mm. As the arsenal for the Brazilian Armed Forces (Army, Navy and Air Force), besides supplying to several military forces worldwide, military ammunition has a daily average production of 1.000.000 rounds of 7.62 mm, 5.56 mm, .50 (12.7 x 99 mm), and other medium calibers and special rounds for training.

The maior volume production is the manufacturing of handgun ammunition for all calibers. The most popular cartridges produced today are calibers .380 AUTO, 40 S&W, 9 mm, 375MAG, 45AUTO, 44MAGNUM and .38. CBC also produces a wide range of rifle cartridges and shotshells. All commercial cartridges made by CBC are sold worldwide under the trade name “MAGTECH” and exported to more than 50 countries over two distribution centers, one in Minneapolis,MN, in the USA and the other in Hamburg, Germany. This ammunition is widely adopted by the Police in more than 20 countries and also by the Armed Forces worldwide.

About 80 percent of CBC’s firearms are exported and the export rate of the ammunition is approximately 70 percent of our total production. Products meet international regulations and are qualified by the Brazilian Armed Forces and the main proof houses in Europe.

The high quality of CBC’s products, recognized internationally, and the fact that it is currently exporting to over 50 countries, assures CBC a prominent position amongst the foremost manufacturers of ammunition and firearms in the world.

A Brief History

Federal Cartridge Company

900 Ehlen Drive

Anoka, MN 55303-7503

1-800-322-2342

Fax: (763) 323-2506

Federal Cartridge Contact Form

Federal Cartridge Website

From Federal Cartridge Company Website:

Federal Cartridge Company

The Ammunition Industry's Technology Leader

Highlights:

*Federal is a wholly-owned subsidiary of Edina, Minnesota-based ATK

*Federal manufactures a complete line of shotshell, centerfire and rimfire ammunition and components

*Nearly 1,000 employees work at the Anoka, Minnesota facility

*The facility is located on 175 acres in Anoka County and spans the border of Anoka and Coon Rapids with half a million square feet of manufacturing space

*Federal Premium® Ammunition is the company's flagship brand and focuses its competitive advantage on cutting edge technology

ATK Website

From ATK Website:

Our History

ATK was launched as an independent company in 1990, when Honeywell spun off its defense businesses to shareholders. The former Honeywell businesses had supplied defense products and systems to the U.S. and its allies for 50 years, including the first electronic autopilot that enabled B-17 aircraft to accomplish pinpoint bombing missions during World War II.

ATK expanded into the aerospace market with the acquisitions of Hercules Aerospace Company in 1995 and Thiokol Propulsion in 2001, which transformed the company into the world's largest supplier of solid propellant rocket motors and a leading provider of high-performance composite structures.

A series of other acquisitions and key contract wins have continued to increase the company's presence in the aerospace, defense, and commercial ammunition markets:

•2000 Selected to operate Lake City Army Ammunition Plant, the U.S. Government's only small-caliber ammunition manufacturing facility.

•2001 Acquired the commercial ammunition businesses of Blount International, which made ATK the nation's largest manufacturer of ammunition.

•2002 Acquired the ordnance business of Boeing, which brought together ATK's munitions portfolio with the products and capabilities of a leading military gun manufacturer.

•2002 Acquired the assets of Science and Applied Technology, Inc., which added critical precision seeker, guidance, and system-level expertise.

•2003 Acquired Composite Optics, Inc., which made ATK the world leader in composite space structures.

•2003 Acquired GASL and Micro Craft, which added leading-edge propulsion and airframe technologies for highly demanding aerospace and defense applications.

•2004 Acquired Mission Research Corporation, which enabled an advanced aerospace and defense technology pipeline spanning concept development to full-scale production.

•2004 Acquired the PSI Group, which strengthened ATK's space systems portfolio and positioned the company to capture emerging opportunities in spacecraft integration and satellite technology.

•2007 Acquired Swales Aerospace, adding enhanced systems engineering and engineering services to ATKs existing space launch, space exploration, small satellite, and spacecraft markets.

•2009 Acquired Eagle Industries as a wholly-owned subsidiary, expanding position in the domestic and international accessories markets serving military and law enforcement customers.

A Brief History

Norinco

12A Guang An Men Nan Jie,Beijing,China

P.O.Box 2932 Beijing

Post Code: 100053

Telephone: (8610)63529988

Facsimile: (8610)63540398

E-mail: info@norinco.com.cn

NORINCO Website

From Website:

China North Industries Corporation (NORINCO) is an enterprise group engaged in both products and capital operation, integrated with R&D, manufacturing, marketing, and services. NORINCO mainly deals with defense products, international engineering contracting, optronic products, chemical products, sports arms & equipment, automobiles and logistics services, etc.

NORINCO faces toward the markets and strives for development of updated high-tech defense products. NORINCO has demonstrated the solid strength of Chinese national defense industry and technology in precision strike systems, amphibious assault weapons and equipment, long-range suppression weapon systems, anti-aircraft & anti-missile systems, information & night vision products, high-effect destruction systems, anti-terrorism & anti-riot products as well as small arms. NORINCO has won trust from clients for its high quality products and excellent services.

While having built its brands in such services as international engineering contracting, logistics and automobiles, NORINCO maintains its competitive edge in chemicals, optronic products, and sports arms based on the integration of technology, manufacturing and trade. NORINCO's subsidiary has been registered in the lead of the global 225 largest international engineering contractors for successive years, and many NORINCO's subsidiaries have also been awarded the national title as advanced enterprise for excellent quality and performance.

By advocating collaboration and mutual benefit, and having made constant efforts to enhance the capabilities of taking the whole situation into account on management of its overseas and domestic markets, NORINCO has established a global operation and information network and formed a worldwide-diversified market setup.

NORINCO will continue to promote product innovations, improve technology & service, share the achievements of development and build a better future with our domestic and international friends!

A Brief History

Manufactured in the 1950's to 1960's by Peters Cartridge Division of Remington Arms. Bridgeport, CT

Impressed "P" on headstamp found on match grade ammunition only.

See also: AFTE Forum post

A Brief History

Eldorado Cartridge Corporation

P.O. Box 62508

Boulder City, NV 89006-2508

(800) 456-9182 (Voice), (702) 294-0121 (Fax)

Sales Department

sales@pmcammo.com

For questions about the location of your nearest PMC dealer, becoming a PMC dealer or distributor, or Law Enforcement or Government Agency sales.

Marketing Department

marketing@pmcammo.com

For questions about PMC advertising or public relations, or general information about PMC products.

Customer Service

customerservice@pmcammo.com

Ballistics

ballistics@pmcammo.com

For questions about the ballistic properties of PMC Ammunition.

From Website:

The original parent company, a U.S. corporation registered in Delaware, was founded in the late 1970's in New York as Patton Morgan Corporation. It began operations by importing military style small arms ammunition and .22 rimfire ammunition manufactured in South Korea. The ammunition was sold then, as it still is, under the registered brand name "PMC Ammunition", and the original slogan, "Precision Made Cartridges" has never changed.

Several years later, the company moved to Los Angeles, California, and its name was changed to Pan Metal Corporation. In addition to its ammunition business, the company also dealt in other facets of the metals business. Early in the 1980's, the increasingly successful ammunition line was expanded to include hunting (soft point) cartridges in the rifle calibers, and hollow points in the handgun ammunition.

In 1988, factory facilities were purchased near Boulder City, Nevada, for the production of ammunition to supplement the Korean imports, and for the purpose of producing two new lines of high performance cartridges. These were the Starfire handgun ammunition for law enforcement and home and personal defense, and X-Bullet rifle ammunition for big game hunting, which were introduced to the market in late 1991. In 1996, shotgun shells were added to the line.

The factory is operated under the name Eldorado Cartridge Corporation, and is a subsidiary of Pan Metal Corporation.

Today, the company's continuously expanding small arms ammunition product selection includes a full line of centerfire rifle and pistol ammunition, rimfire ammunition, shotgun shells, and reloading components. Recently, a new company known as B.C. Outdoors was incorporated and became a part of the "Eldorado Cartridge Corporation Group of Companies." B.C. Outdoors imports the Verona line of quality superposed shotguns from Italy. The company's stated purpose, like that of Eldorado Cartridge Corporation, is "to provide high quality outdoor products to its customers at a reasonable price."

During its more than two decades of ammunition production and sales, PMC Ammunition has become very well known in the United States and other countries of the world as a source of high quality small arms cartridges. The firm is now considered the fourth largest ammunition company in the United States.

A Brief History

RUAG Ammotec GmbH

Kronacher Strasse 63

90765 Fürth

Deutschland

RWS Website

From Website:

RWS stands for the Rheinisch-Westfälischen Sprengstoff factories, which became part of Dynamit Nobel in 1931. RWS rifle cartridges have conquered the world since their introduction to the market and are appreciated by hunters just as much as by sport shooters. Numerous Olympic winners prove the excellent quality of RWS ammunition, which is trusted by many well-known and competent top shooters.

A Brief History

Swartklip division of Denel

Ammunition currently distributed through Armcorp USA

Armscorp USA Website

A Brief History

Swartklip division of Denel

Ammunition currently distributed through Armcorp USA

Armscorp USA Website

A Brief History

Arms Corporation of the Philippines

Armscor Ave.

Parang

Marikina City 1800

Philippines

Phone: (632)941-6243/44 941-4252 941-8279

Fax: (632)942-0682

E-mail: armscor@info.com.ph

Arms Corporation of the Philippines Website

USA

Armscor Precision, Inc.

150 N. Smart Way

Pahrump, NV 89060

Phone: 775-537-1444

Fax: 775-537-1446

Armscor Precision Website

From the Armscor website:

In 1905, two Englishmen named Roy Squires and William Bingham put up a photo print shop and merchandising firm in the Philippines. The company established was called Squires, Bingham & Co.

Squires and Bingham eventually expanded their business to general trading; importing and retailing motorcycles and sporting goods - including firearms and ammunition. By the 1930's, Squires Bingham Co. had become popularly associated with sporting guns. It was at this point in time that Arthur D. Hileman, an ex-US Army Hospital Corpsman, purchased the store from its original owners.

In 1941, the store - referred to as the "Sportsmen's Headquarters" - found a new owner in Celso S. Tuason. Unfortunately, just four months after he purchased the store, World Ward II broke out and Japan invaded the Philippines! Naturally, the invaders first order of business, much to dismay of Don Celso, was to confiscate all the firearms in his store. To survive, Squires Bingham Company had to rely on its clothing and haberdashery during those dark years.

After the war, due to foreign exchange controls, Don Celso Tuason decided to venture into manufacturing. He focused on the most popular and profitable item in the store - firearms and ammunition. Like most countries after World War II, it was a time of rebuilding. Thus, in 1952, the President of the Philippines granted the Tuason family permission to manufacture firearms and ammunition locally as it was in line with his governments thrust towards industrialization. This led to the birth of Squires Bingham Manufacturing. Inc.

In the mid-1960's, Don Celson Tuason decided that it was time to turn over the management of the Company to his three sons - Bolo, Butch and Conkoy. In 1980, Squires Bingham Co., Inc. became the holding company of the Celso S. Tuason family and their varied business interests. Don Celso's eldest son, Demetrio "Bolo" Tuason, was chosen to be the Chairman and President of the manufacturing company for firearms and ammunition. Thus, Arms Corporation of the Philippines (Armscor) was born.

A Brief History

Manufacturer of .22 LR ammuntion

Tippmann Arms

2955 South Maplecrest Rd.

Fort Wayne, IN 46803

Call us at 260 245 6155

A Brief History

The United State Cartridge Company was incorporated in 1868 in Lowell, Massachusetts, by a group of investors including Benjamin F. Butler, a lawyer, entrepreneur and brigadier-general in the Union Army during the Civil War.

A Brief History

From Website:

POBJEDA is the company with recognized industrial tradition having large production and technological possibilities. POBJEDA is well known manufacturer of initiating items for various commercial and sport purposes.Within its engineering activities, POBJEDA can lead 'turn key' projects for transfer of technology, independently and cooperation with world known manufacturers. POBJEDA is focused to developing the existing and introducing new technologies, by monitoring the world achievements in order to preserve the reputation of capable competitor who is equal to internationally known manufacturers in the field of its production program. In certain spheres, the level of technical achievements and product quality meets European and world requirements. This company is well known trough out the world by the products made in its plants. It sells its products in distant Australia and Malaysia, as well as in the USA, not to mention European countries.

INITIATING BLASTING SUPPLIES ACCESSORIES

Electric detonators (instantaneous, half quarter and millisecond delay interval, seismic, permissible, with various grades and delay intervals

Blasting caps No. 6 and No. 8

Delay elements for detonating fuse (relays)

SPORTING AND HUNTING AMMUNITION

Rim fire ammunition: .22 short; .22 long z (indoors); .22 LR standard and HV

Primers: Gevelot 5,73; W-209

Blank cartridges: .22 (15 mm long), 6 mm, 8 mm, 9 mm (.380), 9 mm PA

Blank revolvers and rifles: start revolvers, toy revolvers, toy rifles

Pistol's ammunitions caliber 9 mm Luger - Parabelum

Hunting ammunition (various types and calibers)FOR FASTENING SISTEM

Special cartridges for industrial purposes: 5,6/15; 6,3/10; 6,3/12; 6,3/16; 6,8/1 1; 6,8/1 1 M; 6,8/18; 9x17; 10x17 FOR STUNNING SYSTEM

Cartridges: 5,6/15 mm (.22); 10x11 mm; 9x17 mm

CONTACT ADDRESS:

POBJEDA-GORAZDE

Visegradska bb 73000 Gorazde Bosnia and Herzegovina

Phone: ++387 38 221 336

++387 38 221 150

Fax: ++387 38 221 335

A Brief History

Nammo Lapua Oy

Lapua Site

P.O.Box 5

FIN-62101 Lapua, Finland

Tel. company +358 6 431 0111

Fax +358 6 431 0317

Lapua Website

From Website:

History of Nammo Lapua Oy

1923

Lapua Ltd. was founded on 23rd May 1923. During 1927 the name of the factory was made official: State Cartridge Factory (Valtion Patruunatehdas). During the first years the business was quite modest. The political situation of world politics rapidly changed before World War Two, production got off to a good pace. In the year 1946 the cartridge factory was incorporated into the State Metal Factory.

1946

In connection with war indemnity payments Lapua developed a new product: conveyor and power transmission chains. The first rimfire cartridges were produced in 1947.

1955

The factory was incorporated under control of the Ministry of Defence in 1955.

1976

In 1976 the company decided to build up a new loading station about 6 km away from the city centre at the Jouttikallio industrial area. The next step was to build a new factory for case and bullet production. The new factory was brougt into use in 1984.

1980

In the eighties the company concentrated heavily on product development: sales increased in the civil sector. As the marketing and product development got stronger, Lapua Ltd. became more competitive in manufacturing sporting, hunting and law enforcement cartridges.

1991

At the turn of 1991, the corporate form of the Lapua Cartridge Factory was changed into a limited liability company. At the same time the company got a new name: Cartridge Factory Lapua Ltd. At the beginning of 1992 Lapua Ltd. bought a cartridge factory in Germany: SK Jagd- und Sportmunitions GmbH. The product selection of the new factory completes and supports the products of the parent company

1996

A decision of reorganizing the defence equipment industry was made in 1996 when the parliament of Finland, in connection with the approval of a supplementary budget, gave its consent to the establishment of a state-owned consolidated corporation in the defence equipment industry.

The Group, which started its activities under the name of Finnish Defence Equipment Ltd, was established 5 September 1996. The present name, Patria Industries Oyj, was adopted in April 1997.

1998