- Rifling Methods of Factory Fitted 9 mm Luger (9 x 19 mm) Pistol Barrels: A Reference Resource - Review

- The Formation and Persistence of Toolmarks in the Cartridge Case Head Forming Process - Review

- The Solution for Inconclusives - Review

- The Miami Barrel - Review

- Electrical Discharge Machining and Its Application to Bunter Manufacturing - Review

- Consecutively Made Cartridge Cases - Review

- Subclass Characteristics: From Origin to Evaluation - Review

Member's Area - Machining & Subclass -

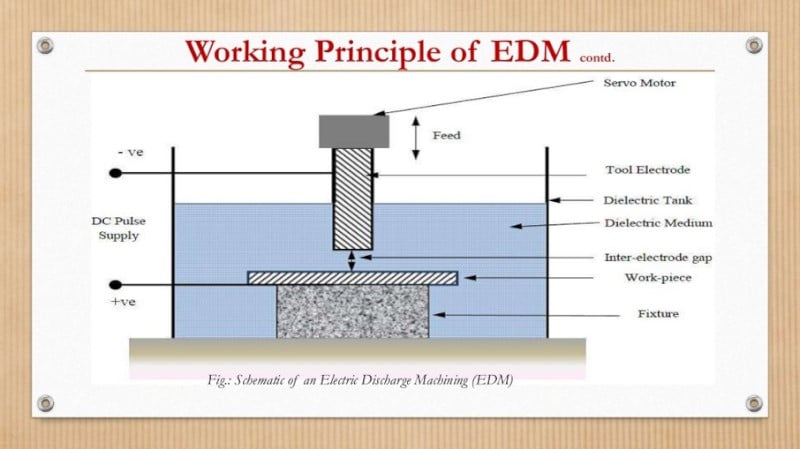

Manufacturing Methods - EDM

← Back to Manufacturing Methods

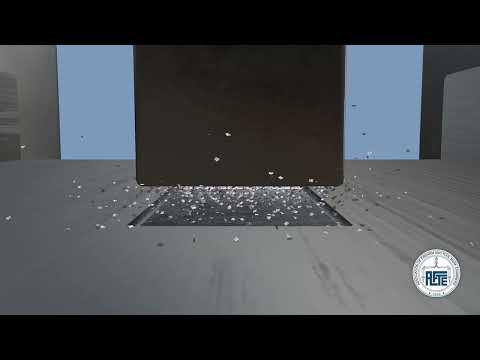

Video

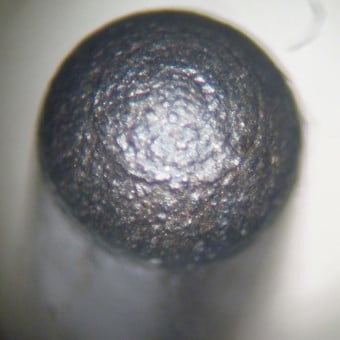

Images

Related Class Characteristics

Related Tools

Definition

No Potential for Subclass Carryover

EDM (Electrical Discharge Machining) – Metal removed by a rapid spark discharge between different polarity electrodes, one on the work piece and the other the tool separated by a gap distance of 0.013 to 0.9 mm (0.0005 to 0.035 in.). The gap is filled with dielectric fluid and metal particles that are melted, in part vaporized, and expelled from the gap.

Subclass carryover would not be expected on a work piece machined using EDM. This is due to the random nature of the spark gap interaction with the work piece. The surface of the work piece may have a pitted, granular like appearance when viewed under magnification.