Member's Area - Machining & Subclass -

Manufacturing Methods - Honing

← Back to Manufacturing Methods

Video

Images

Related Class Characteristics

Related Tools

Definition

No Potential for Subclass Carryover

Honing – A low-speed finishing process used chiefly to produce uniform high dimensional accuracy and fine finish, most often on inside cylindrical surfaces. In honing, very thin layers of stock are removed by simultaneously rotating and reciprocating a bonded abrasive stone or stick that is pressed against the surface being honed with lighter force than is typical of grinding.

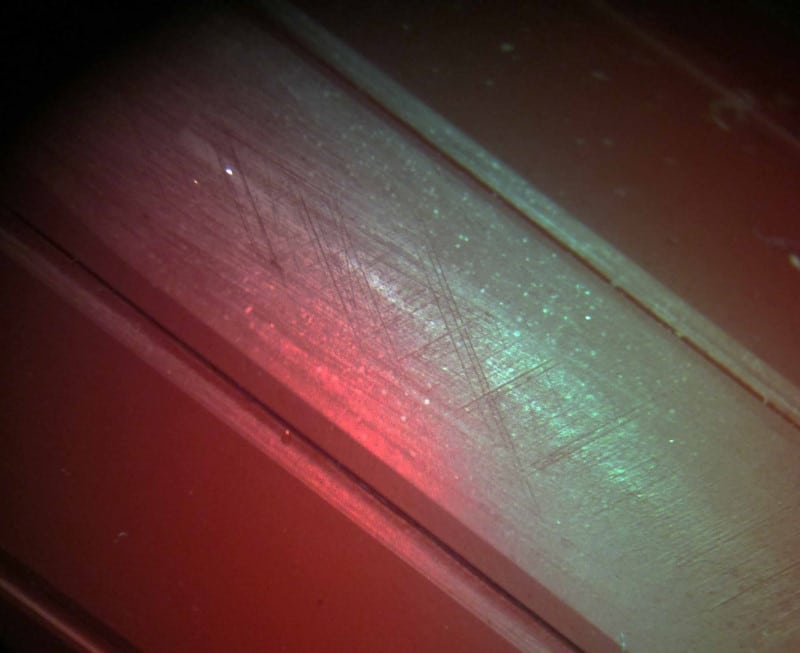

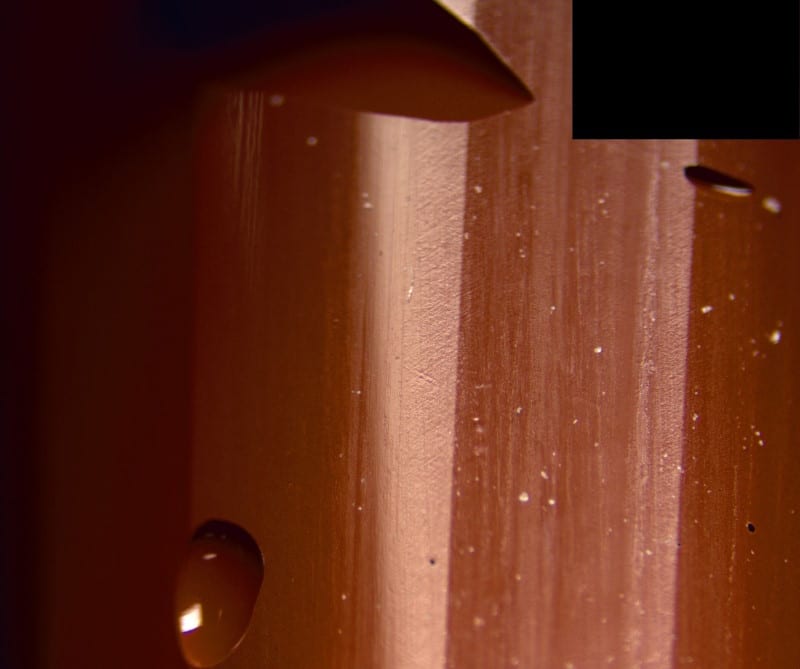

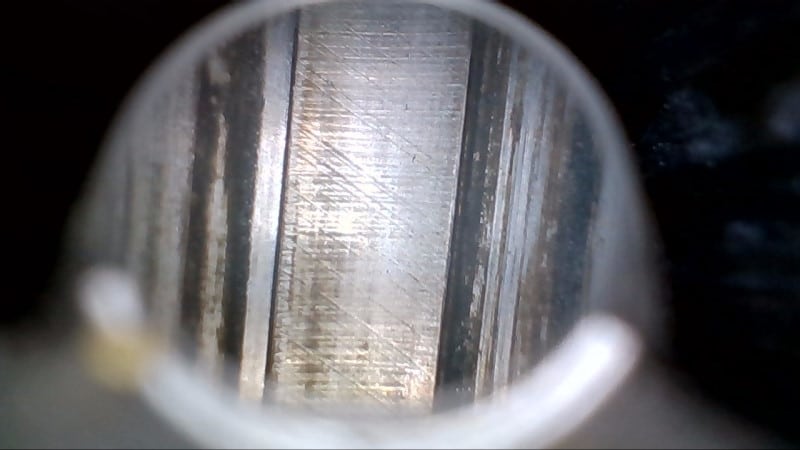

Honing in firearms manufacturing is typically limited to barrels and is used to remove any rough surfaces on the inside of the bore. This rotating action will leave tool marks that appear as a cross-hatch pattern. The random imperfections caused by the honing marks cannot repeat and are NOT parallel to the bore or in line with the rifling and thus cannot be subclass. Therefore, as the bullet travels down the barrel, an individual striated pattern will be imparted on its surface.