Member's Area - Machining & Subclass -

Manufacturing Methods - Plunge Milling

← Back to Manufacturing Methods

Video

Images

Related Class Characteristics

Related Tools

Definition

Potential for Subclass Carryover

Plunge milling – In plunge milling, the cutting is performed at the end of the tool instead of at the periphery.

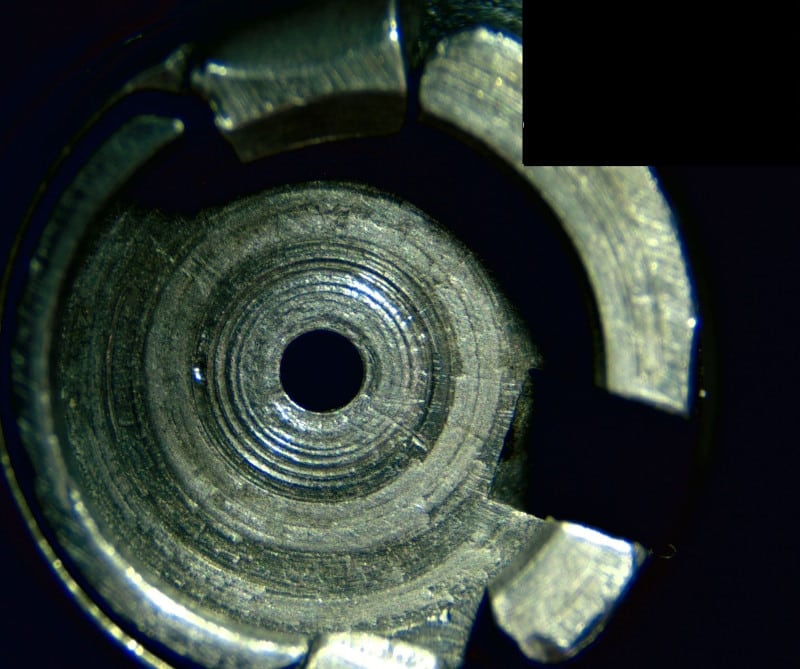

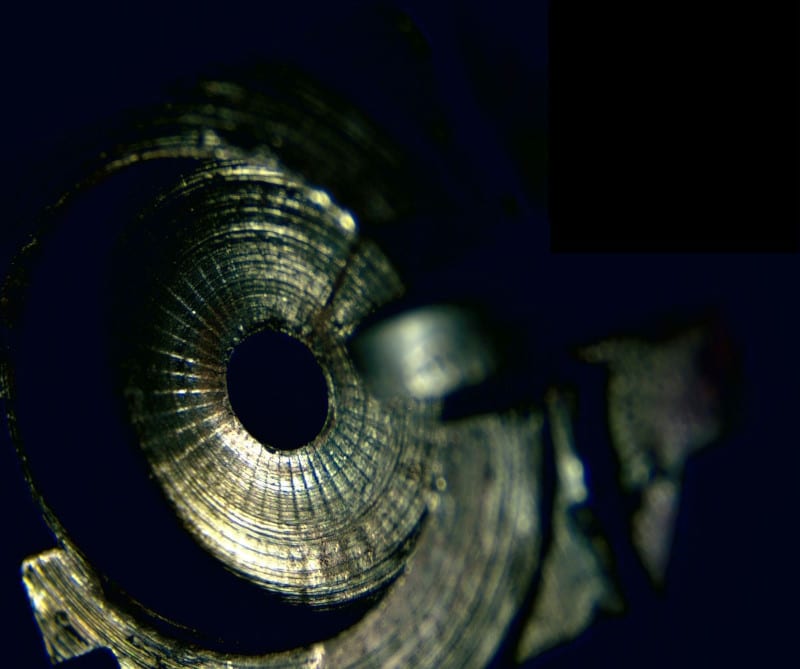

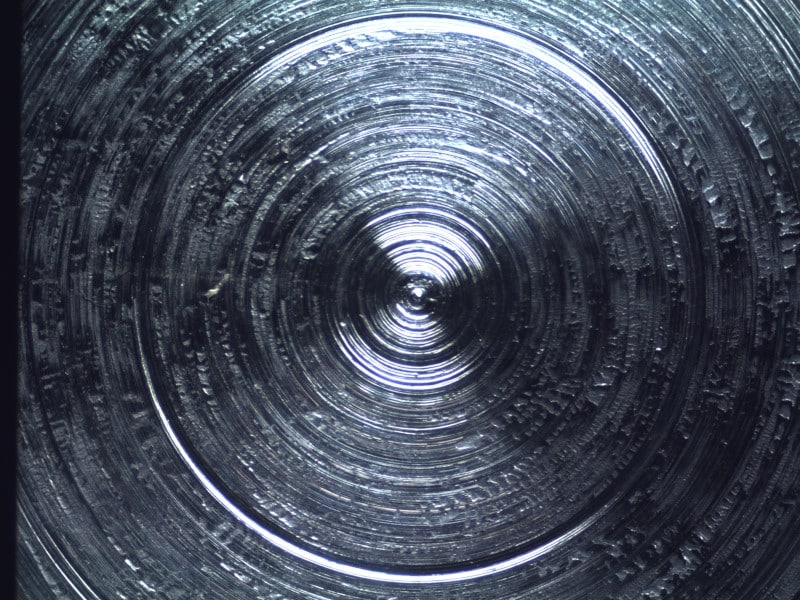

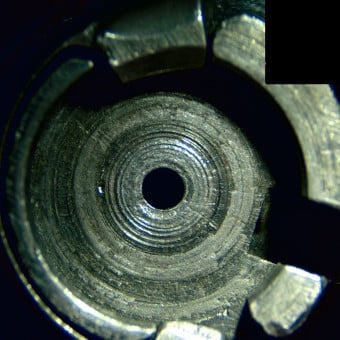

The subclass characteristics displayed by plunge milling appear as concentric circles as seen below. This overall pattern may repeat from work piece to work piece depending on the state of wear of the tool surface. To evaluate concentric circular marks for the presence of subclass, align the marks being evaluated on the two items placing them in phase. Then rotate one of the items 180 degrees, which will knowingly place the items out of phase. If correspondence is observed between the circular marks, with the items out of phase, then potential subclass carryover is present.

However, due to chip formation, plowing, side flow, built-up edge, etc., individual characteristics can be seen thus creating a unique surface. These individual characteristics appear as start/stop points, changes in direction of circles, voids in the work piece, etc. The photos below also illustrate that subclass characteristics do not have to be evenly spaced and/or consist of relatively gross/wide tool marks.