Member's Area - Machining & Subclass -

Manufacturing Methods - Gang Broach (Rifling)

← Back to Manufacturing Methods

Video

Images

Related Class Characteristics

Related Tools

Definition

Potential for Subclass Carryover

Gang Broach -A tool having a series of cutting edges (buttons) of slightly increasing height is used to cut spiral grooves in a barrel. All grooves are cut with a single pass of the broach.

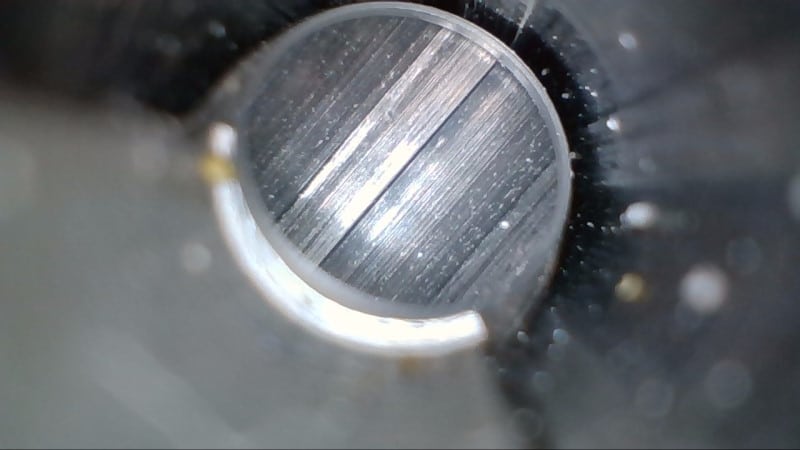

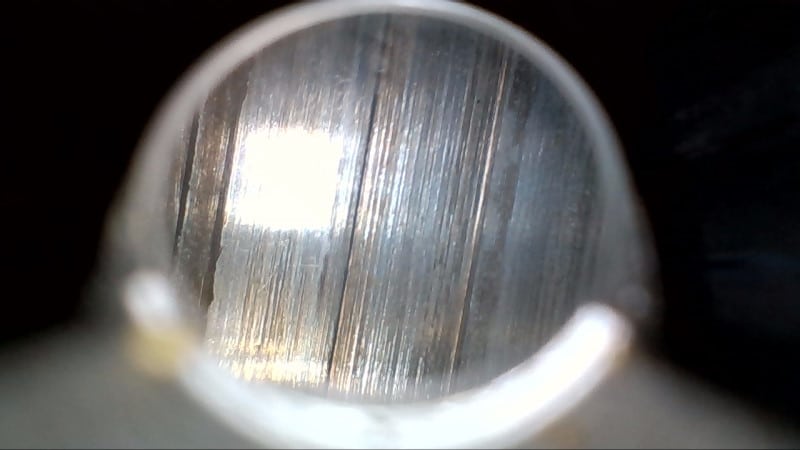

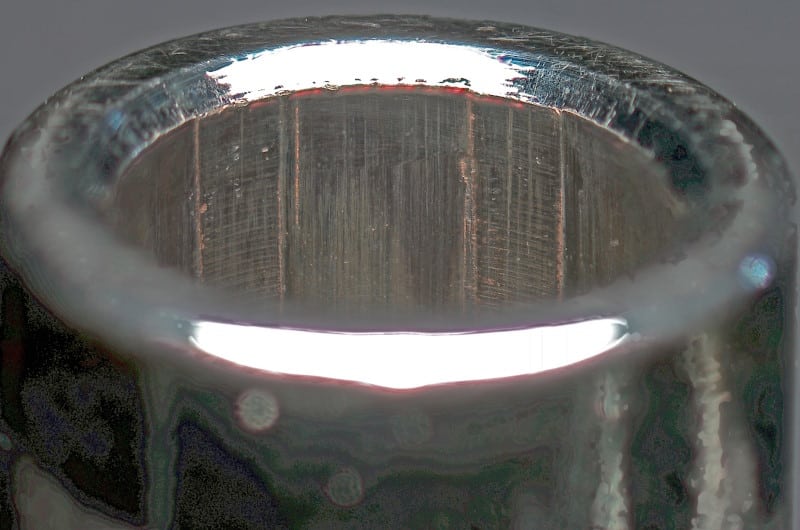

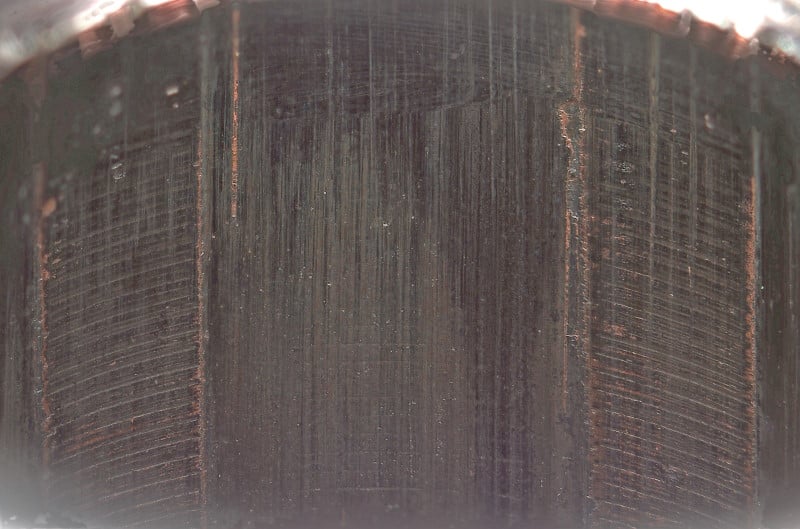

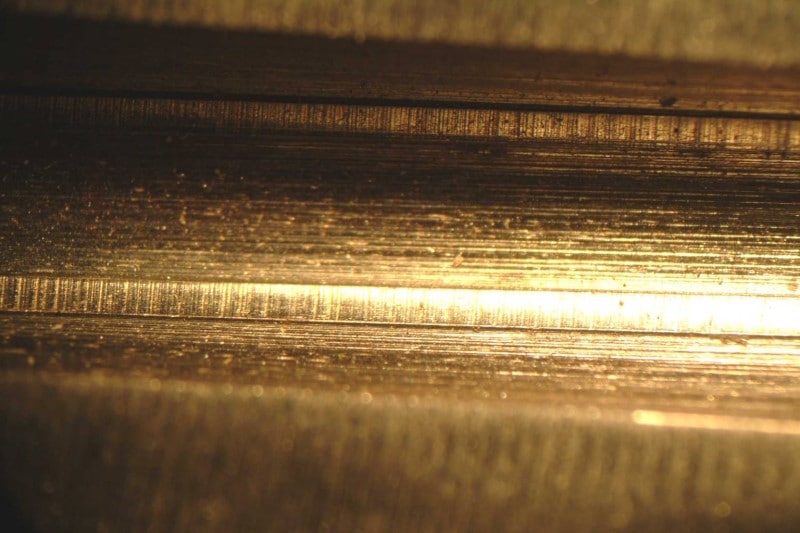

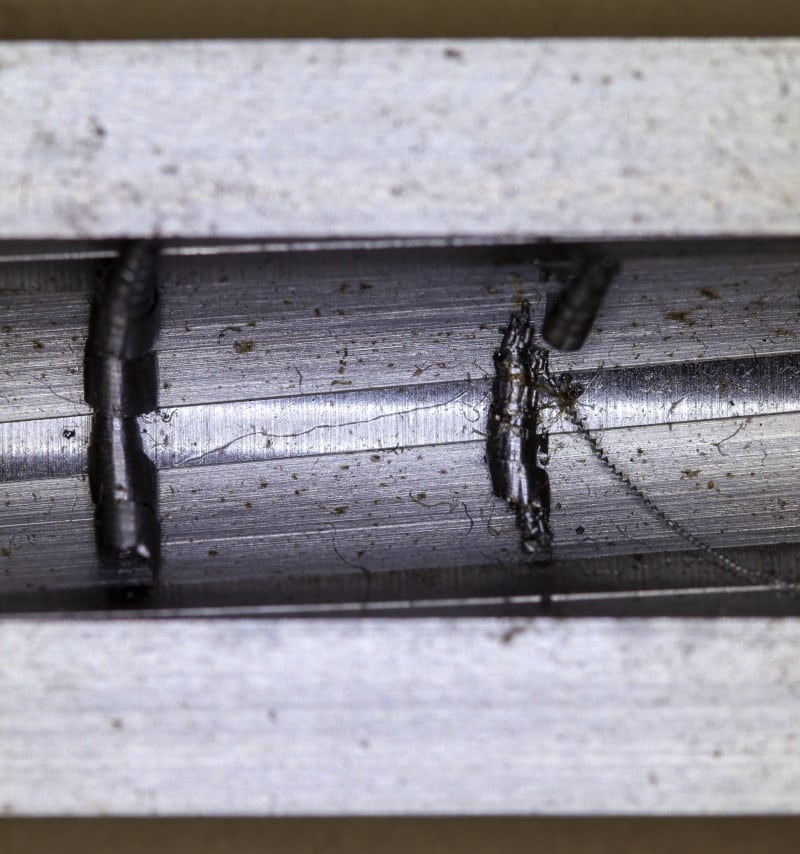

Gang broaches are used to impart rifling to barrels. This broaching method can impart potential subclass characteristics to a workpiece. The cutting teeth of the gang broach are arranged in slightly increasing heights over the length of the broach. Each tooth removes small portions of material from the workpiece, which results in grooves being cut into the barrel’s interior. Potential subclass characteristics arise from defects in the cutting teeth that persist on the broach until changes occur to the cutting surface of the teeth or the broach’s teeth are re-sharpened. Potential subclass characteristics may appear as continuous line that extended the length of the barrel and run parallel to the rifling. To evaluate for potential subclass influence, barrel casts at the muzzle and chamber ends can be made and then intercompared. Those marks which appear continuous across the surface when the opposing ends are intercompared maybe potential subclass in nature.

However, areas of individual characteristics may also be imparted to during manufacturing due to chip formation, tool wear, or through wear, tear, use, and abuse of the workpiece. These areas would appear as random, non-continuous marks with various starting and stopping point along the surface of the work piece.