- Drilling Toolmarks Discovered on the Underside of an Explosively Formed Projectile Liner - Review

- Characteristics of the Drilling Process - Review

- Letter to the Editor: “Drilling Toolmarks Discovered on the Underside of an Explosively Formed Projectile Liner,” by Steve Scott, AFTE Journal, Vol. 51, No 1, Winter 2019, pp 31-35. - Review

- An Introduction to the Forensic Examination of Toolmarks - Review

- Toolmarks: Examining the Possibility of Subclass Characteristics - Review

Member's Area - Machining & Subclass -

Manufacturing Methods - Drilling

← Back to Manufacturing Methods

Video

Images

Related Class Characteristics

Related Tools

Definition

No Potential for Subclass Carryover

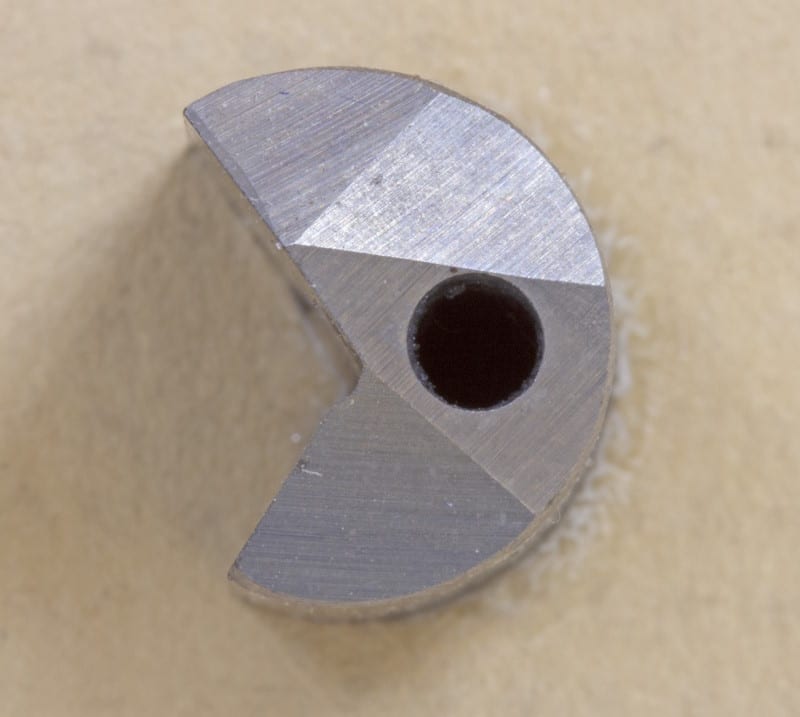

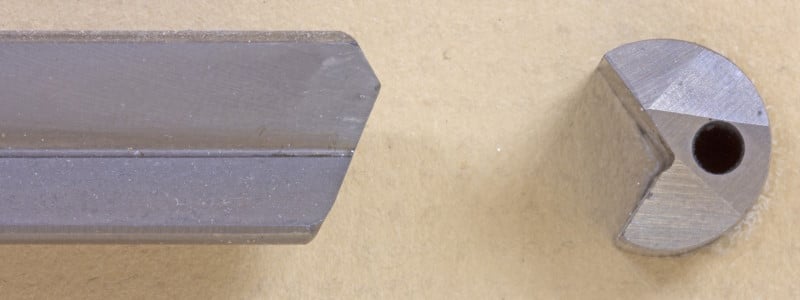

Drilling – Hole making with a rotary end-cutting tool having one or more cutting lips and one or more helical or straight flutes or tubes for the ejection of chips and the passage of a cutting fluid.

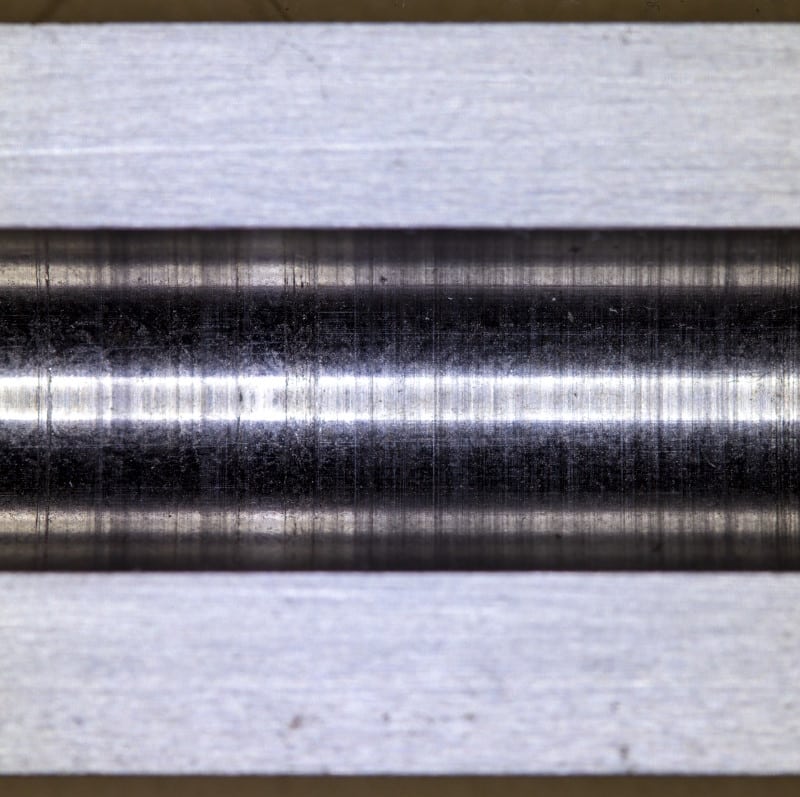

Subclass carryover from the drilling process would not be expected on the work piece. Tool marks imparted by the tool on the interior of the hole/bore being drilled would appear circular throughout the circumference of the hole/bore. These tool marks are perpendicular to axis of the bore and, therefore, are perpendicular to the movement of a fired bullet traveling through the barrel’s bore or in the case of a fired cartridge case, being extracted from the chamber producing an individual pattern on the bearing surface of a bullet or on the side of a fired cartridge case. Tool marks traveling parallel with the axis of the bore do have the potential for subclass carryover.