- Rifling Methods of Factory Fitted 9 mm Luger (9 x 19 mm) Pistol Barrels: A Reference Resource - Review

- Rifling Methods - A Review and Assessment of the Individual Characteristics Produced - Review

- A General Discussion of Gun Barrel Individuality and an Empirical Assessment of The Individuality of Consecutively Button Rifled .22 Caliber Rifle Barrels - Review

- Bullet Markings from Consecutively Rifled Shilen DGA Barrels - Review

- A Comparison of Three Individual Barrels Produced from One Button Rifled Barrel Blank - Review

- Manufacturing the Lorcin L380 and Corresponding Characteristics - Review

- Striae Reproducibility on Sectional Cuts of One Thompson Contender Barrel - Review

- Individual Characteristics Criteria - Review

- Subclass Characteristics in a Gamo Air Rifle Barrel - Review

- An Assessment of the Foundational Validity of Firearms Identification Using Ten Consecutively Button-Rifled Barrels - Review

- An Examination of Five Consecutively Rifled Hi-Point 9mm Pistol Barrels with Three Lands and Grooves Left Twist Rifling to Assess Identifiability and the Presence of Subclass Characteristics - Review

- Perplexing Ballistic Identification Problems with Contemporary Hi-Point C9, 3-Left 9mm Pistols - Review

- An Introduction to the Forensic Examination of Toolmarks - Review

- Toolmarks: Examining the Possibility of Subclass Characteristics - Review

- Subclass Characteristics: From Origin to Evaluation - Review

Member's Area - Machining & Subclass -

Manufacturing Methods - Button Rifling

← Back to Manufacturing Methods

Video

Images

Related Class Characteristics

Related Tools

Definition

Reduced Potential for Subclass Carryover

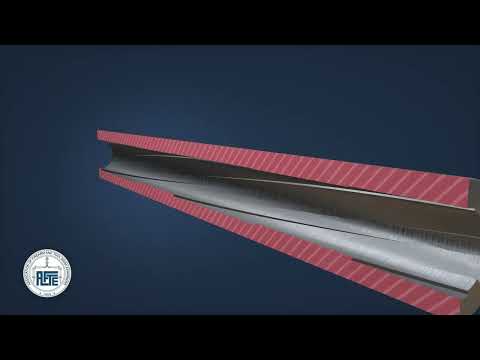

Button rifling – A process in which grooves are pressed into the interior of the barrel using a tool called a button. The button is made from solid carbide, is larger than the reamed bore, and is either pulled or pushed through the bore, depending upon the type of machinery used.

Due to the fact that button rifling primarily displaces/compresses the metal inside the barrel to form the rifling, many of the circular marks from the drilling and/or reaming are not obliterated. As with those processes, the tool marks remaining are perpendicular to the bore therefore imparting individual characteristics on the bearing surface of a bullet (see drilling, reaming). One other factor contributing to the creation of individual characteristics on a bullet surface, is that although this method is a swaging process, there is some cutting occurring at the intersection of the button and the shoulder of the land/groove (see photo). This cutting creates metal buildup which in turn can impart a unique pattern on the bullet surface.