- Identification of Lathe Shavings - Review

- A Comparison of Manufacturing Marks on Smith & Wesson Firing Pins - Review

- Individual Characteristics Criteria - Review

- Identification of Toolmarks Present on Additive Manufactured Components - Review

- An Introduction to the Forensic Examination of Toolmarks - Review

- Toolmarks: Examining The Possibility of Subclass Characteristics - Review

- Subclass Characteristics: From Origin to Evaluation - Review

Member's Area - Machining & Subclass -

Manufacturing Methods - Lathe Turning

← Back to Manufacturing Methods

Video

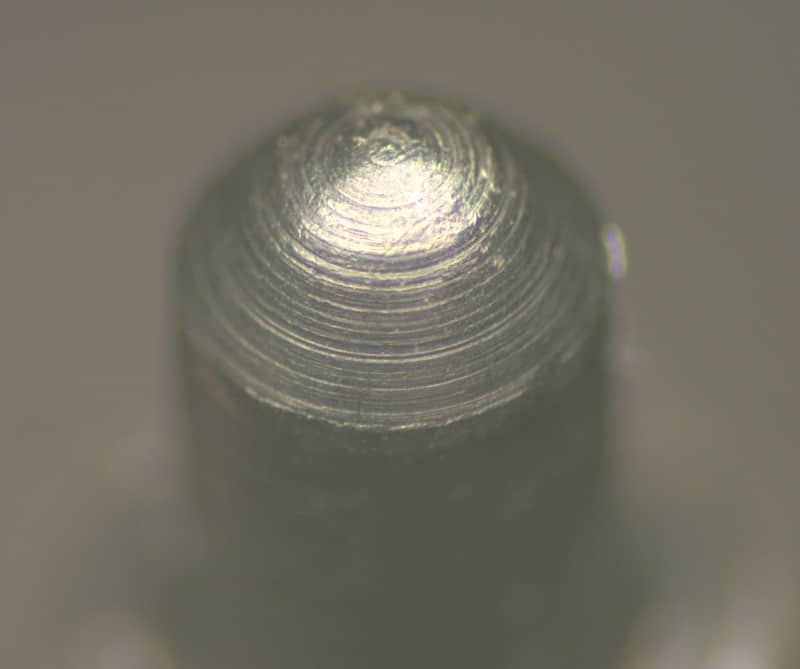

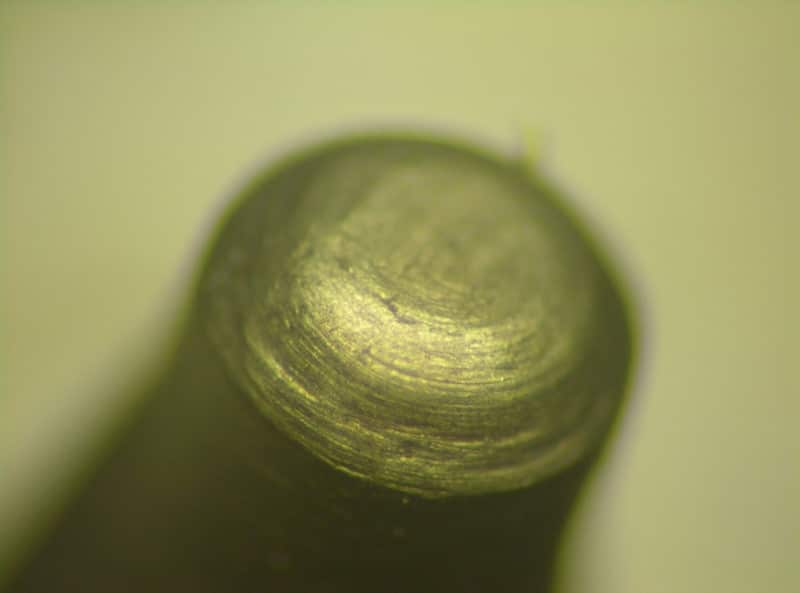

Images

Related Class Characteristics

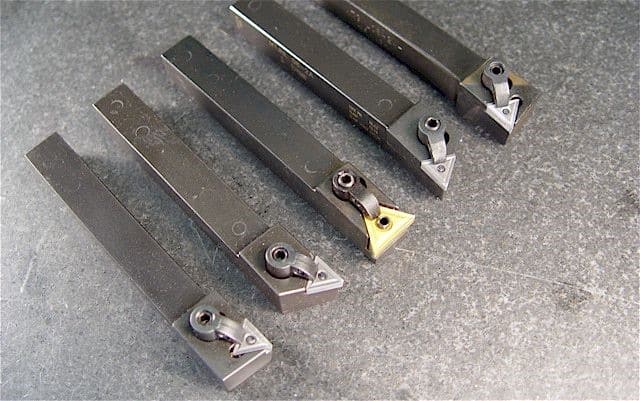

Related Tools

Definition

Potential for Subclass Carryover

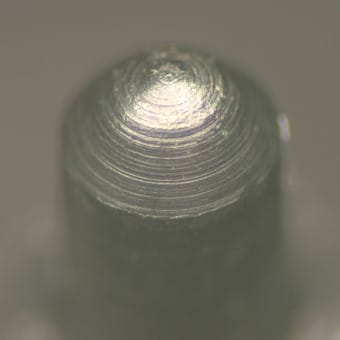

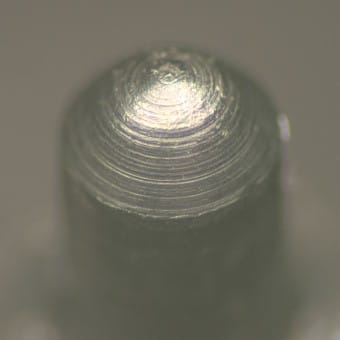

Lathe turning – Removing material by forcing a single-point cutting tool against the surface of a rotating work piece. The tool may or may not be moved toward or along the axis of rotation while it cuts away material.

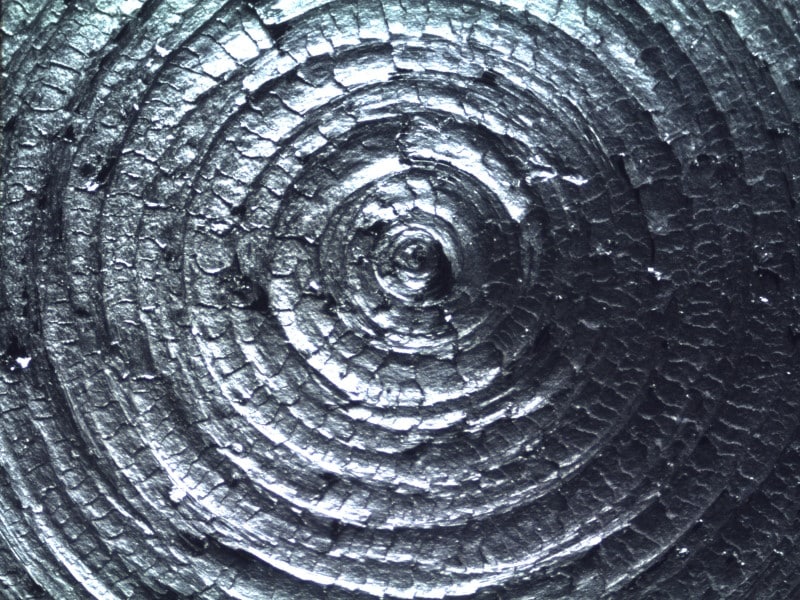

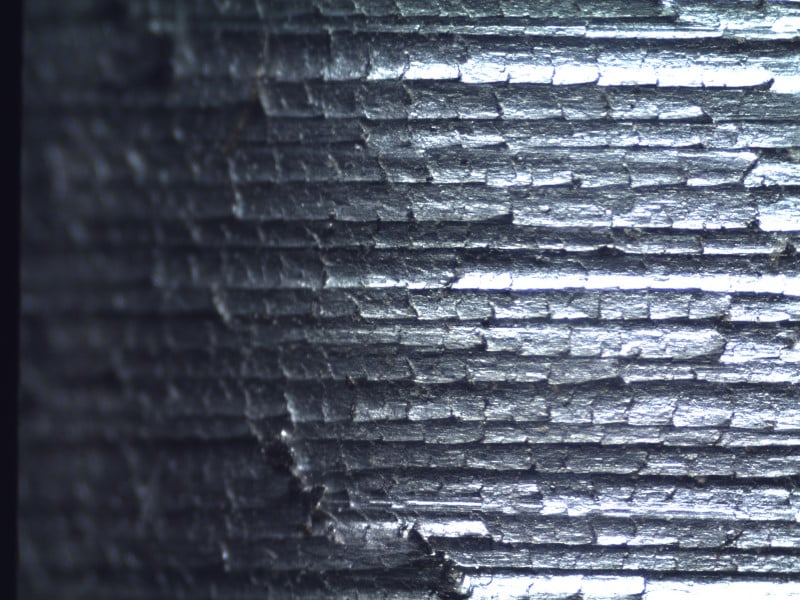

Turning a work piece on a lathe will produce either a set of concentric circles or a spiral pattern on the surface that is cut. This pattern is considered subclass because this overall pattern will typically repeat on multiple work piece surfaces. As with other machining methods that create concentric circles, individual characteristics will generally still be created while the work piece is being cut. This is because there will still be chip formation, built up edge, chattering, etc., that cause random, irregular imperfections throughout the concentric circles or spirals.