- Identification Problems with Sawed-Off Rifled Gun Barrels - Review

- The Origin of Some Markings on Fired Bullets - Review

- An Introduction to the Forensic Examination of Toolmarks - Review

- Toolmarks: Examining the Possibility of Subclass Characteristics - Review

- Subclass Characteristics: From Origin to Evaluation - Review

Member's Area - Machining & Subclass -

Manufacturing Methods - Reaming

← Back to Manufacturing Methods

Video

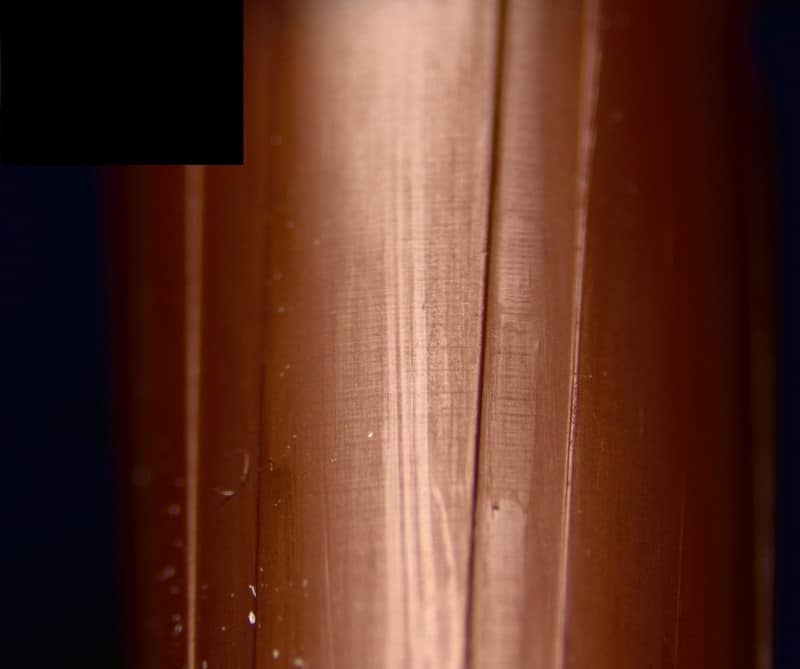

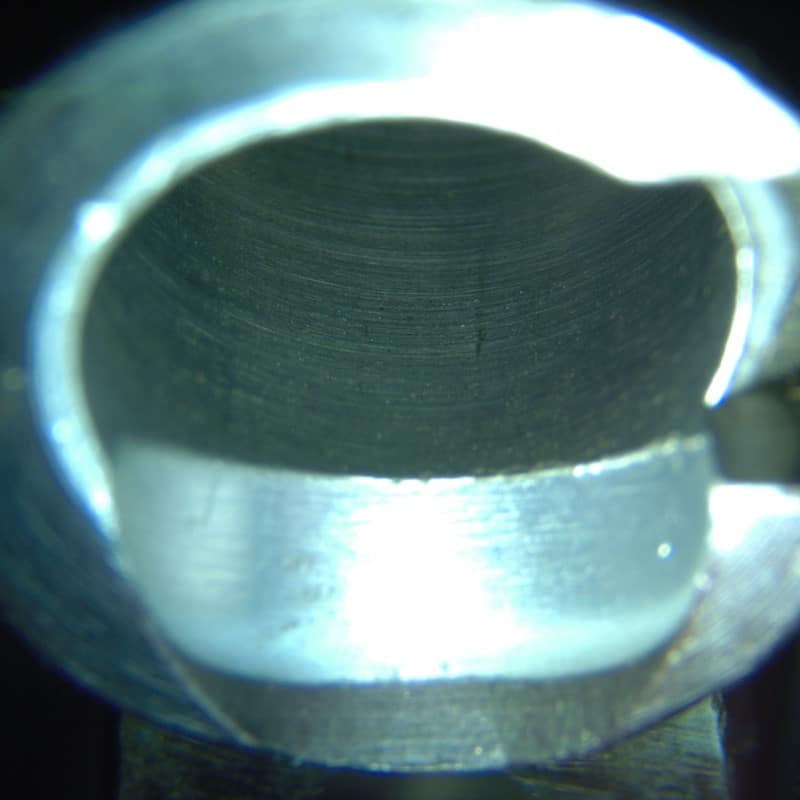

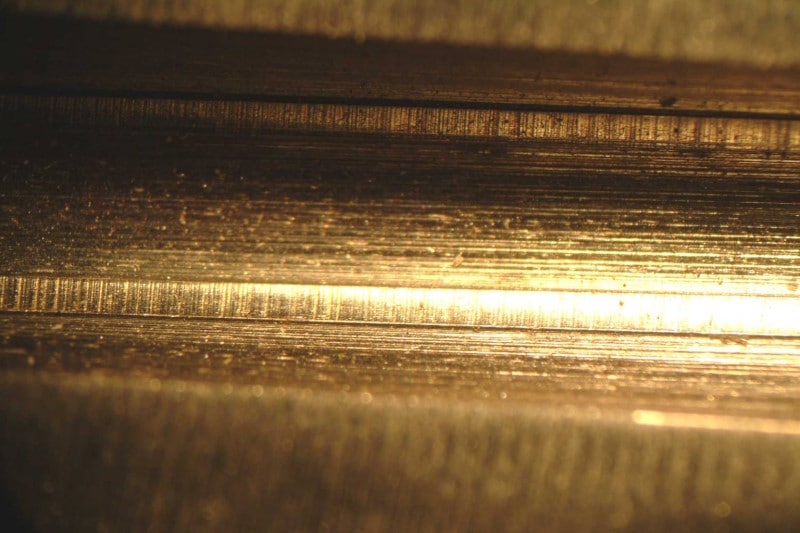

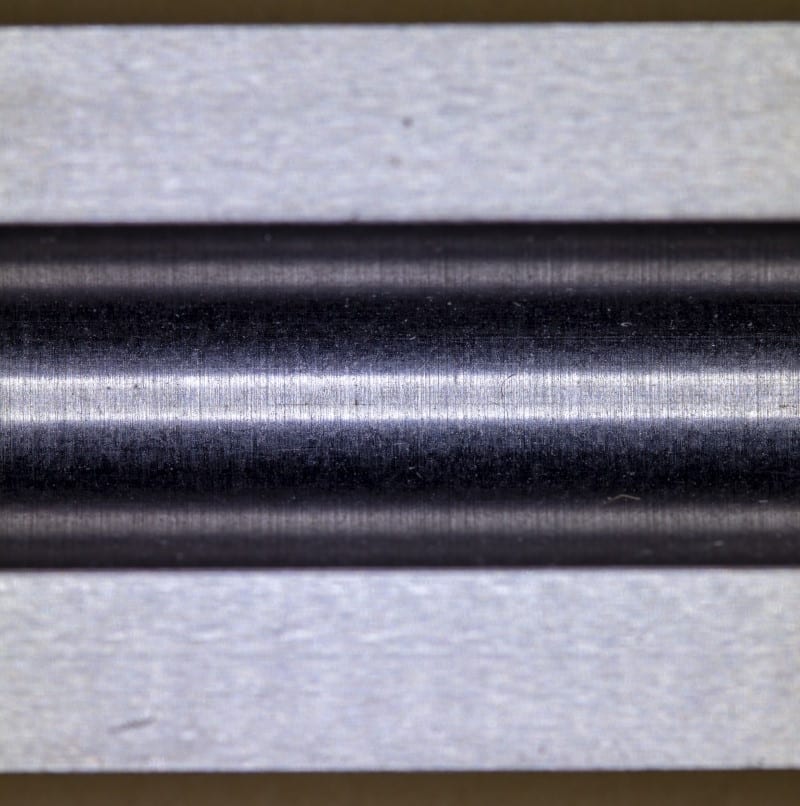

Images

Related Class Characteristics

Related Tools

Definition

No Potential for Subclass Carryover

Reaming- An operation in which a previously formed hole is sized and contoured accurately by using a rotary cutting tool (reamer) with one or more cutting dements (teeth). The principal support for the reamer during the cutting action is obtained from the work piece.

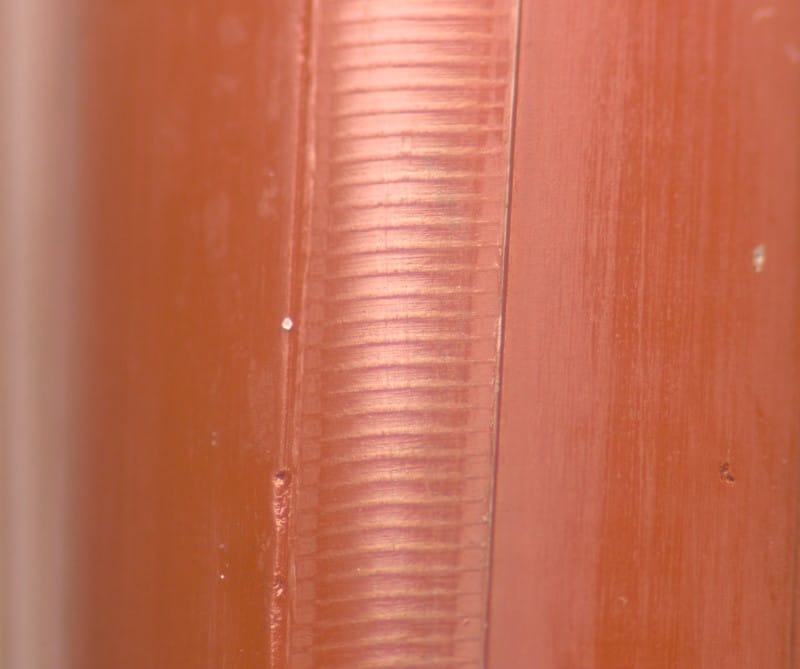

Subclass carryover from the reaming process would not be expected on the work piece. Tool marks imparted by the tool on the interior of the hole/bore being reamed would appear circular throughout the circumference of the hole/bore. In firearms, these tool marks are perpendicular to axis of the bore and, therefore, are perpendicular to the movement of a fired bullet traveling through the barrel’s bore or a fired cartridge case being extracted from the chamber. This interaction, between the item and the perpendicular tool marks within the bore will produce a unique pattern on the bearing surface of a bullet or the sides of a fired cartridge case.