- False Breech Face ID's - Review

- Lorcin L9mm and L380 Pistol Breech face Toolmark Patterns - Review

- Comparison of Dust Cover Impact Marks on 200 Consecutively Fired Cartridge Cases from a Saiga 7.62x39mm Rifle - Review

- An Introduction to the Forensic Examination of Toolmarks - Review

- Toolmarks: Examining the Possibility of Subclass Characteristics - Review

Member's Area - Machining & Subclass -

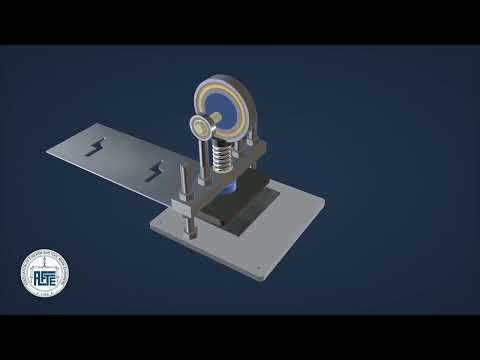

Manufacturing Methods - Stamping

← Back to Manufacturing Methods

Video

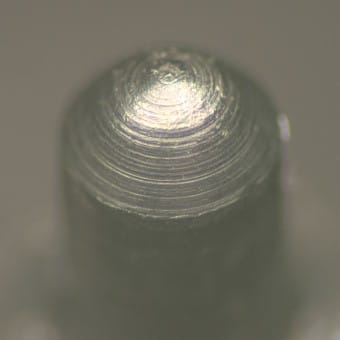

Images

There are no images yet for this entry.

Related Class Characteristics

Related Tools

Definition

Potential for Subclass Carryover

Stamping – A general term used to denote all sheet metal press-working. It includes blanking, shearing, hot or cold forming, drawing, bending, or coining.

The most likely location for subclass carryover will be any part of the work piece that comes into contact with the face of the stamping tool. This is because there is no metal removal on either the stamping tool or the work piece. Without metal removal there is no change to the stamping tool. There is also the potential for subclass carryover along any edge of the work piece if any metal is sheared.