- Glock Marking Barrels – An Evaluation of Individual and Subclass Characteristics 2016 Volume 48, Number 3 (Summer), Page 169 thru 172 - Review

- Rifling Methods of Factory Fitted 9 mm Luger (9 x 19 mm) Pistol Barrels: A Reference Resource - Review

- Polygonal Rifling - Review

- Heckler & Koch Polygonal Rifling - Review

- Bullet Identification From H&K USP Polygonal Barrels - Review

- Individual Characteristics Criteria - Review

- The Miami Barrel Saga Continues - Review

- Glock Experiments with New Prototype Rifling Method Barrel - Review

- An Introduction to the Forensic Examination of Toolmarks - Review

- Subclass Characteristics: From Origin to Evaluation - Review

Member's Area - Machining & Subclass -

Manufacturing Methods - Hammer Forging

← Back to Manufacturing Methods

Video

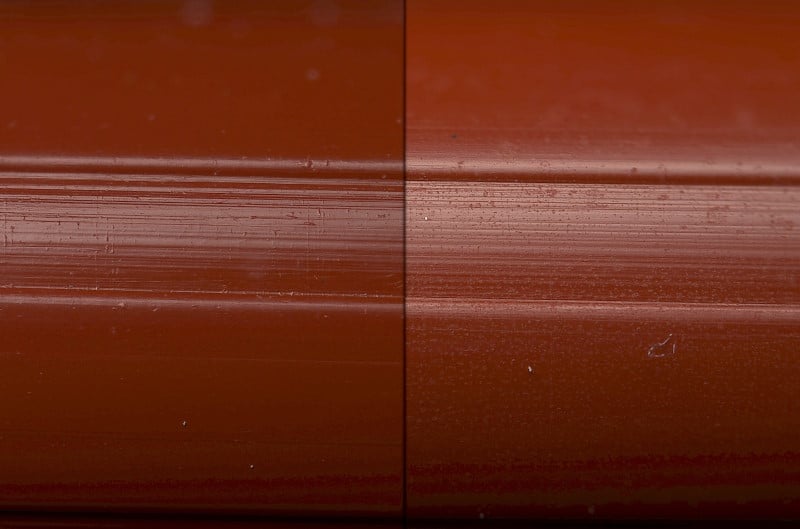

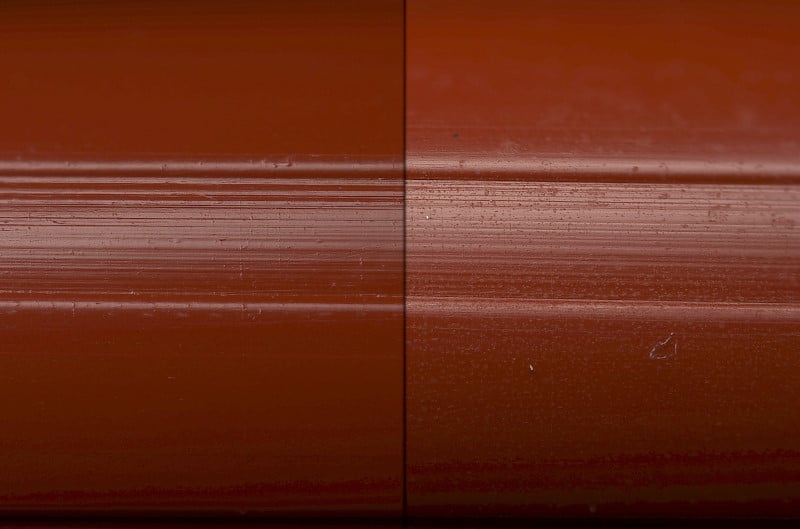

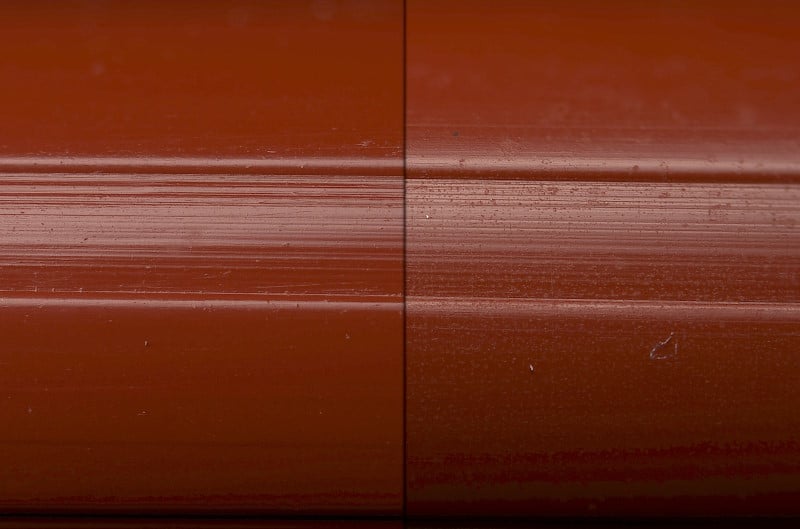

Images

Related Class Characteristics

Related Tools

Definition

Reduced Potential for Subclass Carryover**

Hammer forging – Forging in which the work is deformed by repeated blows. In barrel making – the formation of spiral grooves in the bore of a barrel by means of inserting a mandrel with a rifling configuration into the barrel blank. The outer surface of the barrel is machine hammered, forcing the barrel material down against the mandrel causing the inner surface of the barrel to take on the shape of the mandrel.

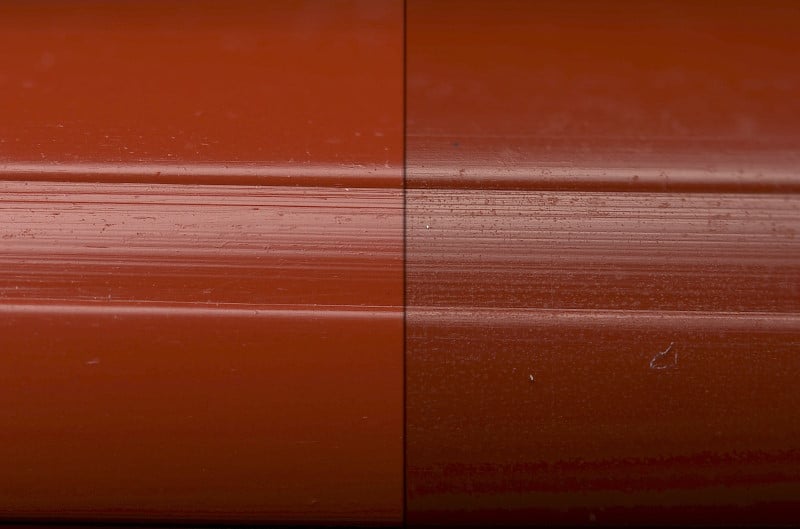

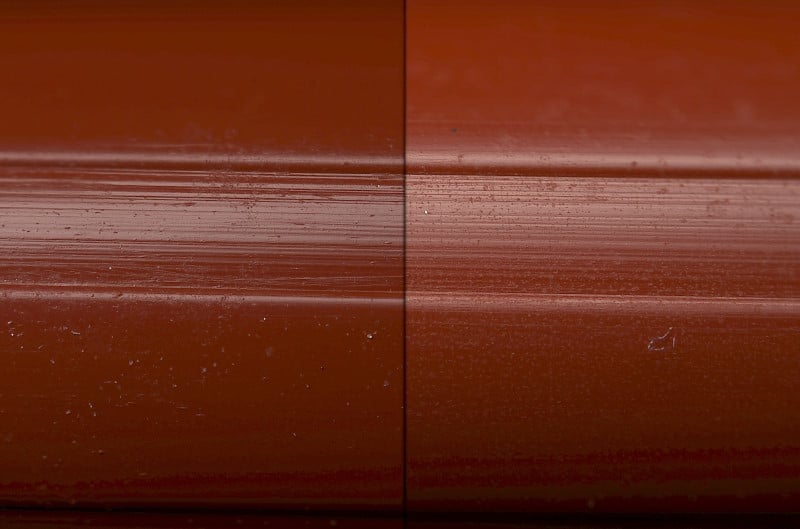

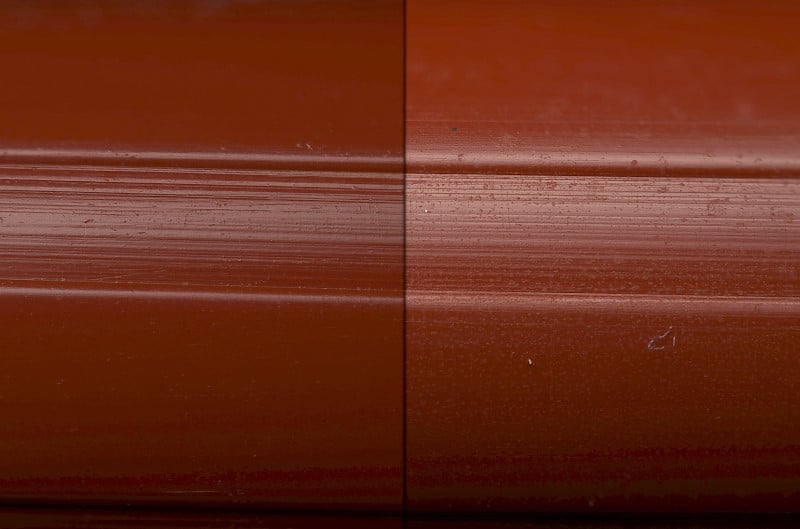

Typically, hammer forged barrels will impart a unique, striated pattern on the surface of a bullet due to:

- A random, imperfect surface found within the rifling created during the hammer forging process – as the barrel is compressed around the mandrel, it is stretched/elongated, thus creating individual characteristics.

- The hammer forging does not completely destroy previous machining marks created during the manufacturing process that do create impart individual characteristics on a bullet surface – drilling, reaming, and/or honing marks.

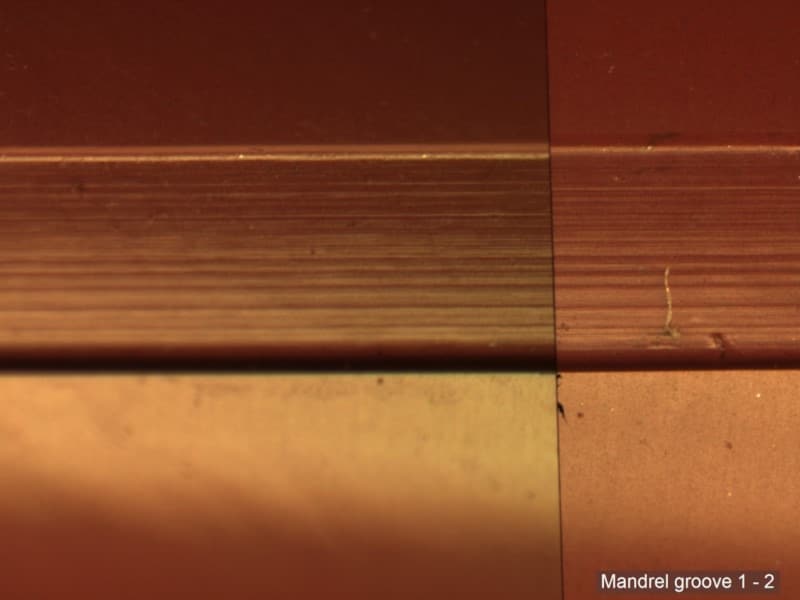

**However, special attention should be given to hammer forged barrels created using mandrels that were shaped using a grinding process which may impart a repeating pattern. The rifling in barrels created using these mandrels will potentially display the same pattern, thus qualifying as subclass characteristics. Therefore, bullets fired through these barrels MAY display a similar striated pattern. Any individual characteristics created imparted on the bullet surface fired through these barrels will be from another source.